Network Design In Supply Chain Presentation

| Introduction to Network Design in Supply Chain | ||

|---|---|---|

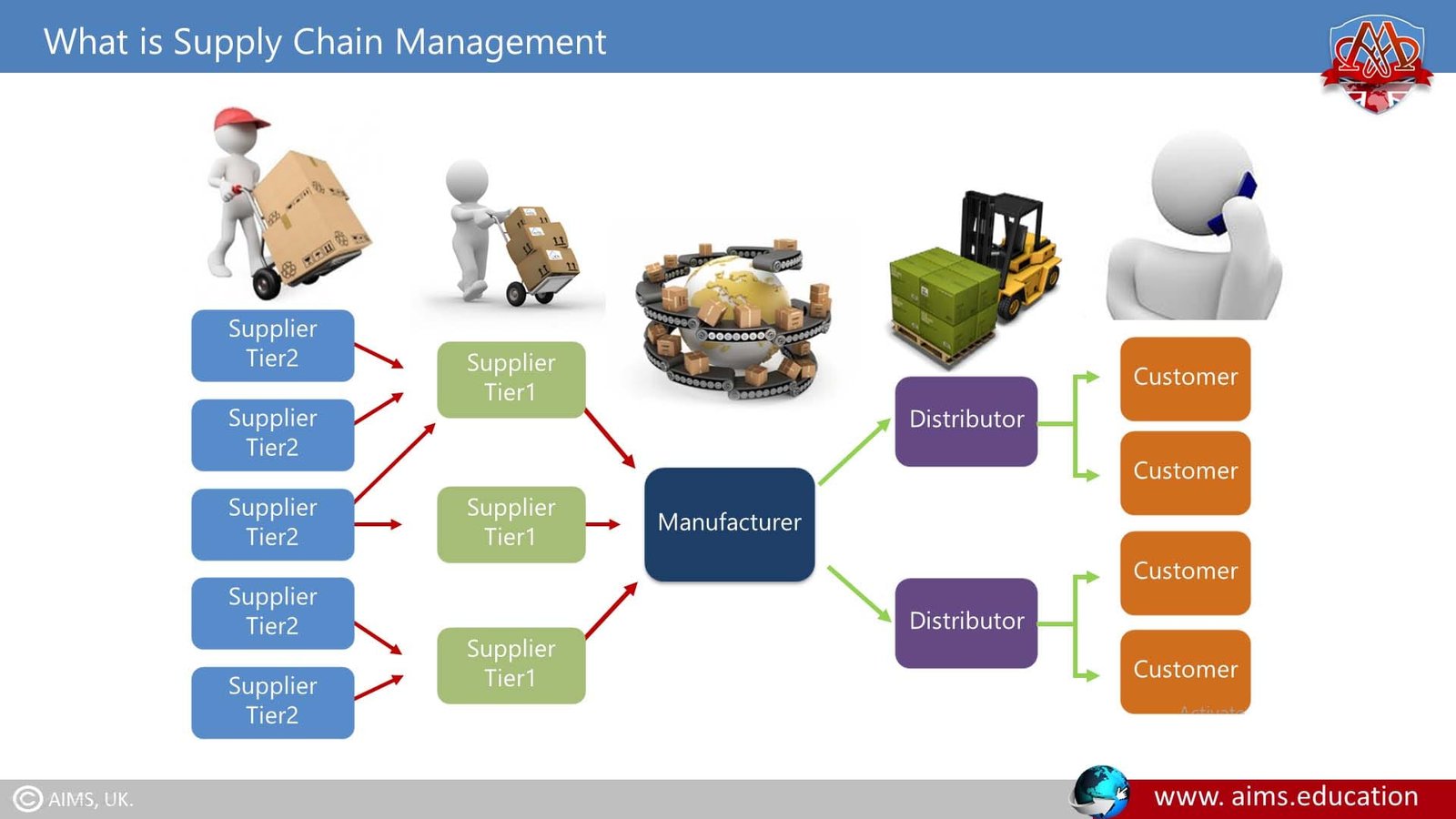

| Network design in supply chain refers to the process of determining the optimal structure and configuration of a supply chain network. It involves strategic decision-making to ensure efficient flow of materials, information, and products across the supply chain. The objective is to minimize costs, maximize customer service levels, and improve overall supply chain performance. | ||

| 1 | ||

| Key Considerations in Network Design | ||

|---|---|---|

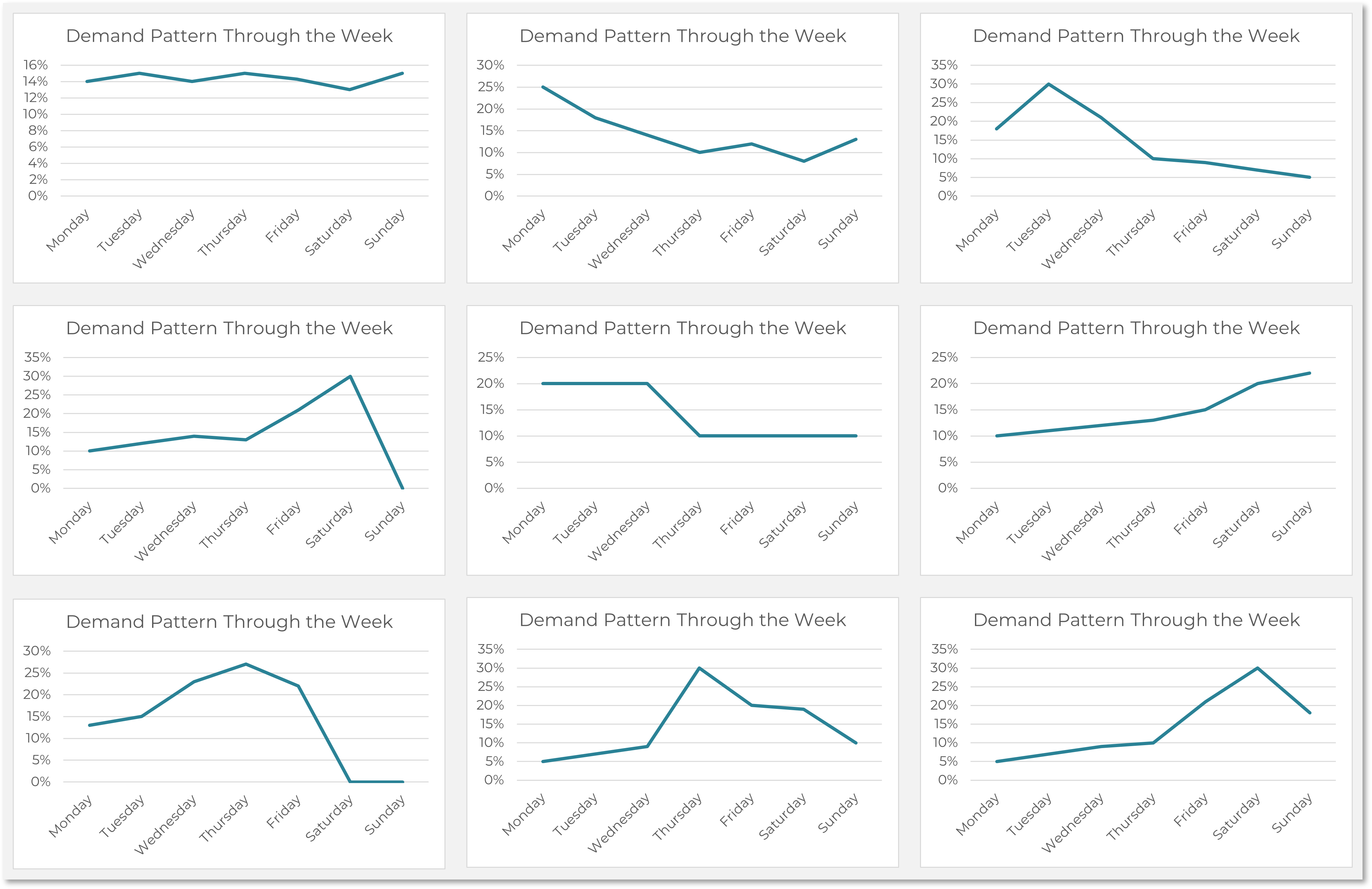

| Factors such as customer demand patterns, product characteristics, and geographical locations must be considered when designing a supply chain network. The network design should align with the overall business strategy and accommodate future growth and changes in the market. The trade-off between transportation costs, inventory costs, and lead times must be carefully analyzed to achieve an optimal network design. | ||

| 2 | ||

| Steps in Network Design Process | ||

|---|---|---|

| The network design process typically includes the following steps:

1. Define objectives and constraints: Clearly identify the goals and limitations of the network design project.

2. Gather data: Collect relevant information on customer demand, product flows, transportation costs, and other factors influencing the network design.

3. Model and analyze: Utilize mathematical optimization models and simulation tools to evaluate different network design scenarios.

4. Develop alternatives: Generate multiple network design alternatives considering various factors and constraints.

5. Evaluate and select: Assess the alternatives based on predefined criteria and select the most suitable network design.

6. Implement and monitor: Execute the chosen network design and continuously monitor its performance to identify areas for improvement. Your second bullet Your third bullet |  | |

| 3 | ||

| Network Design Strategies | ||

|---|---|---|

| There are several network design strategies that can be employed based on the specific requirements of the supply chain:

1. Centralized distribution: Utilize a single distribution center to serve multiple locations, reducing transportation costs and improving inventory management.

2. Decentralized distribution: Establish multiple distribution centers closer to the end customers, enhancing responsiveness and reducing lead times.

3. Hybrid network: Combine elements of centralized and decentralized distribution to optimize cost-efficiency and customer service levels. Your second bullet Your third bullet |  | |

| 4 | ||

| Tools and Technologies for Network Design | ||

|---|---|---|

| Various tools and technologies are available to support the network design process:

1. Network optimization software: Advanced software solutions that utilize mathematical models to optimize network design decisions.

2. Geographic Information Systems (GIS): Mapping and visualization tools that provide insights into geographical factors influencing network design.

3. Simulation software: Allows for the testing and evaluation of different network design scenarios, enabling informed decision-making. Your second bullet Your third bullet |  | |

| 5 | ||

| Benefits of Effective Network Design | ||

|---|---|---|

| An effective network design in supply chain can yield numerous benefits:

1. Cost reduction: Optimized network design can minimize transportation costs, inventory holding costs, and overall supply chain expenses.

2. Improved customer service: A well-designed network enables faster delivery, reduces lead times, and enhances customer satisfaction.

3. Flexibility and scalability: A robust network design allows for easy adaptation to changes in customer demand, market dynamics, and business growth. Your second bullet Your third bullet |  | |

| 6 | ||

| Real-World Examples | ||

|---|---|---|

| Several companies have successfully implemented network design strategies in their supply chains:

1. Amazon: Utilizes a combination of centralized and decentralized distribution centers to achieve fast and efficient order fulfillment.

2. Procter & Gamble: Optimized its supply chain network by consolidating manufacturing and distribution facilities, resulting in cost savings and improved service levels.

3. Walmart: Implemented a sophisticated network design approach to ensure product availability, reduce transportation costs, and enhance customer experience.

Note: Please make sure to expand on the sub-bullets and add relevant graphics and visuals to enhance the presentation. Your second bullet Your third bullet |  | |

| 7 | ||