Industrially Important Secondary Metabolites Their Production And Downstream Processing Presentation

| Title: Introduction to Industrially Important Secondary Metabolites | ||

|---|---|---|

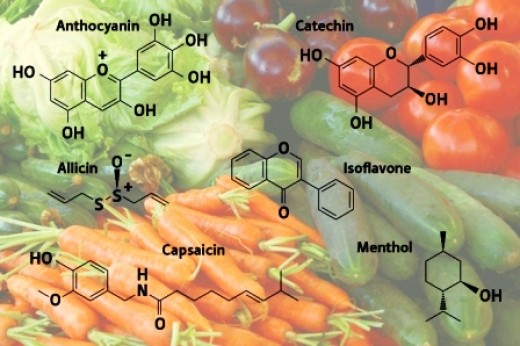

| Industrially important secondary metabolites are chemical compounds produced by microorganisms, plants, and animals. These compounds have various applications in industries such as pharmaceuticals, agriculture, food, and cosmetics. The production and downstream processing of secondary metabolites are crucial for their commercialization and utilization. | ||

| 1 | ||

| Title: Production of Secondary Metabolites | ||

|---|---|---|

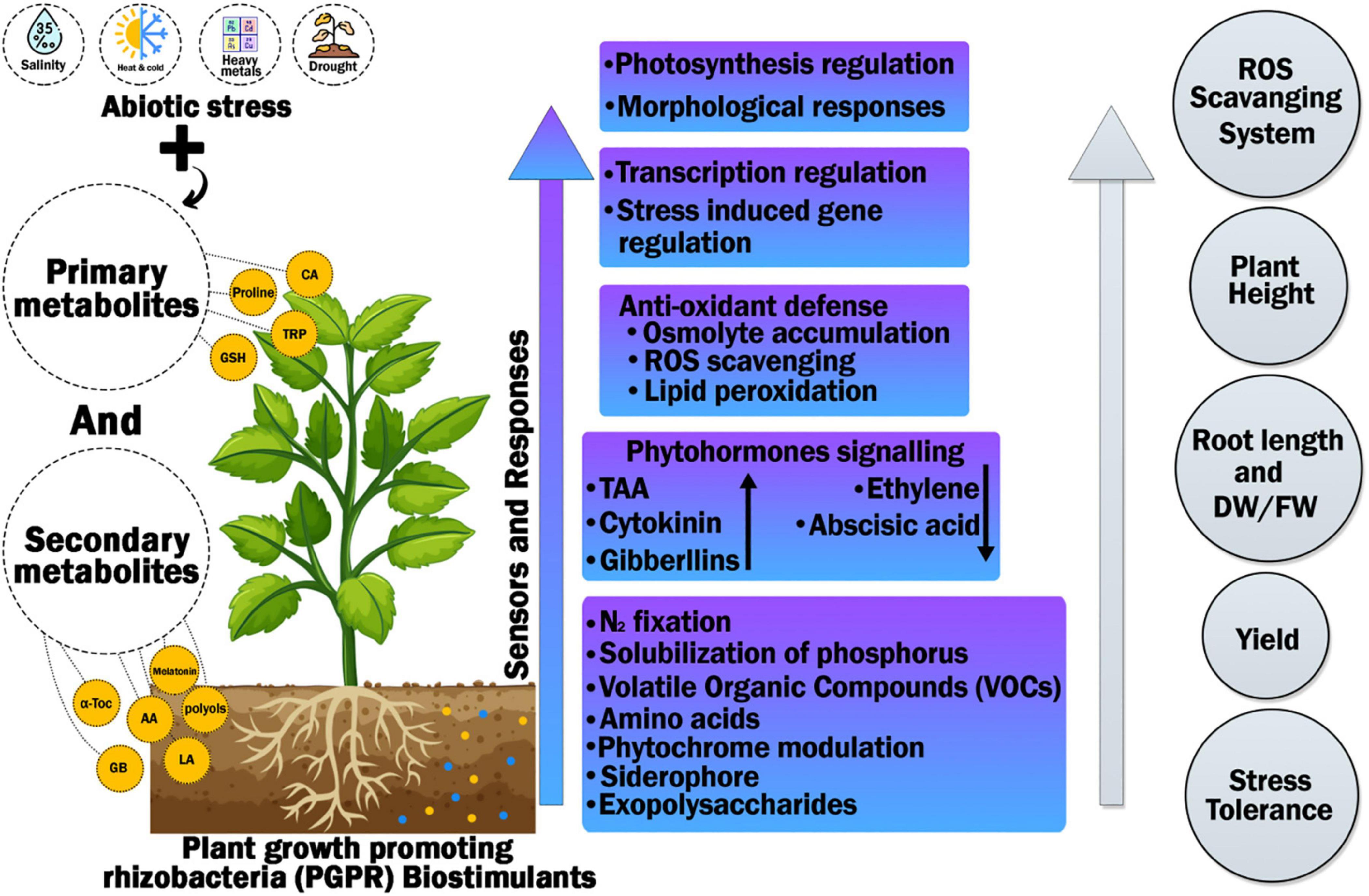

| Secondary metabolites are produced by microorganisms, plants, and animals as a response to environmental factors or stress. Microbial production involves the use of fermentation techniques, where microorganisms are grown under optimized conditions. Plant production involves the extraction of secondary metabolites from plant tissues or the use of plant cell cultures. | ||

| 2 | ||

| Title: Factors Affecting Secondary Metabolite Production | ||

|---|---|---|

| Factors such as temperature, pH, oxygen availability, nutrient composition, and agitation affect secondary metabolite production. Genetic manipulation and metabolic engineering techniques can be employed to enhance production yields. The selection of suitable production hosts and optimization of growth conditions are critical for efficient production. | ||

| 3 | ||

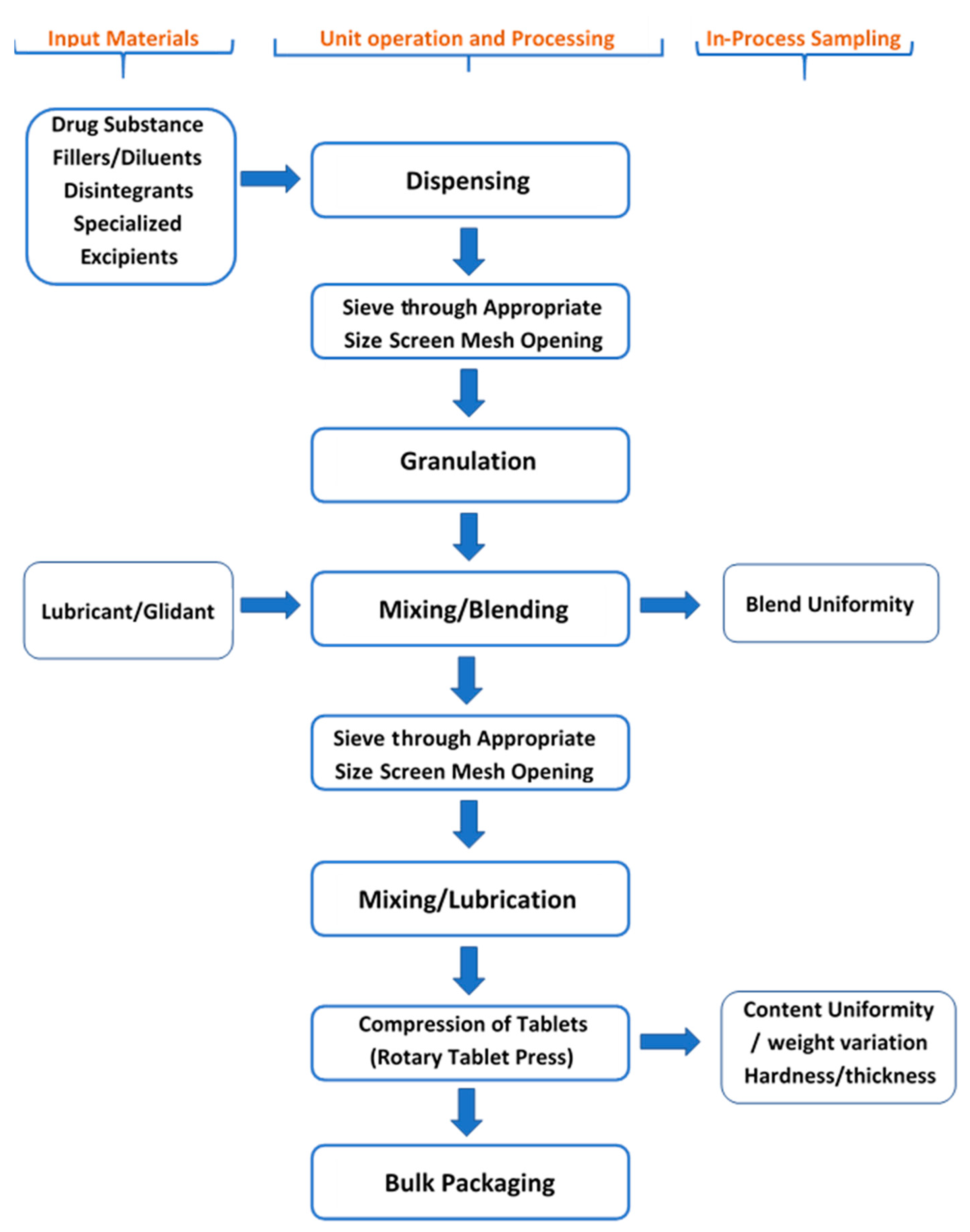

| Title: Downstream Processing of Secondary Metabolites | ||

|---|---|---|

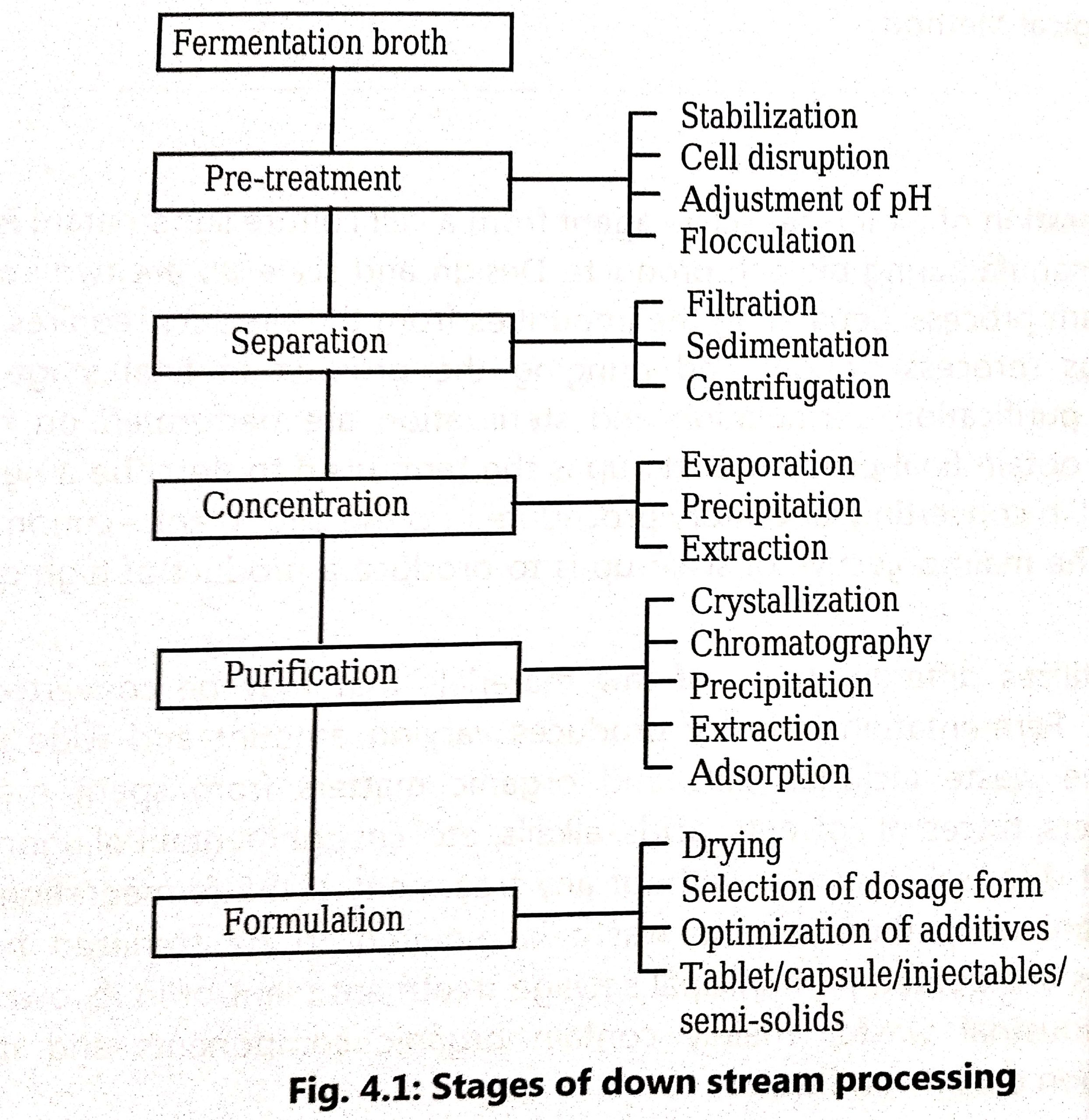

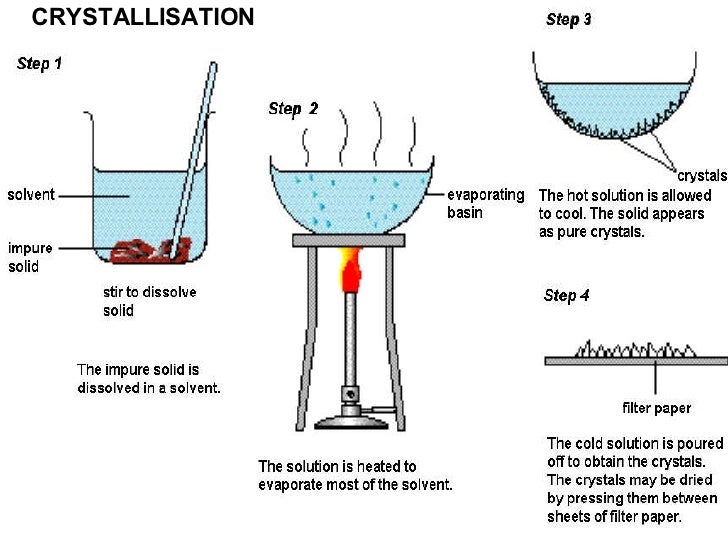

| Downstream processing involves the separation, purification, and formulation of secondary metabolites. Separation techniques such as filtration, centrifugation, and chromatography are used to isolate the target compounds. Purification techniques, including crystallization and distillation, are employed to obtain high-purity secondary metabolites. | ||

| 4 | ||

| Title: Extraction Methods for Secondary Metabolites | ||

|---|---|---|

| Solvent extraction is commonly used to extract secondary metabolites from plant materials or microbial cultures. Other methods include supercritical fluid extraction, microwave-assisted extraction, and enzyme-assisted extraction. The choice of extraction method depends on the nature of the secondary metabolite and the source material. |  | |

| 5 | ||

| Title: Purification Techniques for Secondary Metabolites | ||

|---|---|---|

| Crystallization is a widely used technique for purifying secondary metabolites based on their solubility. Distillation is employed for the separation of volatile secondary metabolites from non-volatile impurities. Other purification techniques include adsorption, membrane filtration, and liquid-liquid extraction. | ||

| 6 | ||

| Title: Formulation and Stability of Secondary Metabolites | ||

|---|---|---|

| Formulation involves the development of dosage forms or delivery systems for secondary metabolites. Stability studies are conducted to evaluate the shelf life and storage conditions of secondary metabolite products. Techniques such as encapsulation or microencapsulation can enhance the stability and bioavailability of secondary metabolites. | ||

| 7 | ||

| Title: Applications of Industrially Important Secondary Metabolites | ||

|---|---|---|

| Secondary metabolites have diverse applications in the pharmaceutical industry, where they serve as drug leads or active pharmaceutical ingredients. They are used as natural pesticides and herbicides in the agricultural sector. Secondary metabolites are also utilized in the production of flavors, fragrances, and cosmetic ingredients. | ||

| 8 | ||

| Title: Challenges and Future Perspectives | ||

|---|---|---|

| The production of secondary metabolites on an industrial scale often faces challenges such as low yields and high production costs. Advances in genetic engineering, synthetic biology, and bioprocessing technologies offer opportunities for overcoming these challenges. The discovery of novel secondary metabolites and their potential applications continue to drive research in this field. | ||

| 9 | ||

| Title: Conclusion | ||

|---|---|---|

| Industrially important secondary metabolites are valuable compounds with wide-ranging applications. Their production and downstream processing involve various techniques, including fermentation, extraction, separation, purification, and formulation. Further research and technological advancements are needed to optimize production yields and reduce costs for their commercialization. | ||

| 10 | ||