Improvement On Citric Acid Production In Solid State Fermentation By Aspergillus Niger LPB BC Mutant Presentation

| Introduction | ||

|---|---|---|

| Citric acid production in solid state fermentation (SSF) by Aspergillus niger LPB BC mutant. Importance of citric acid as a key ingredient in various industries. Research objective: To improve citric acid production using the LPB BC mutant. | ||

| 1 | ||

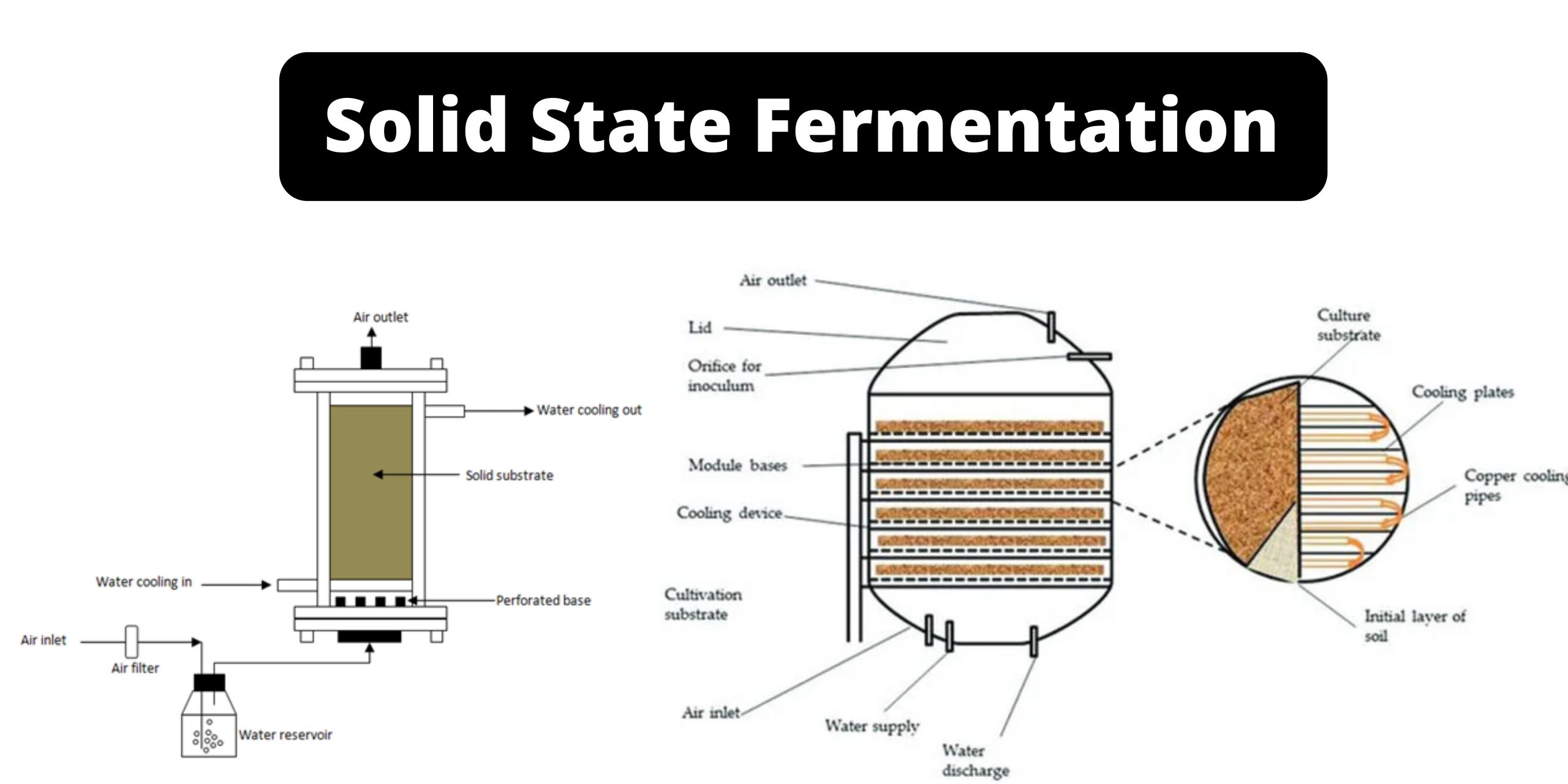

| Solid State Fermentation (SSF) | ||

|---|---|---|

| SSF is a fermentation method where microorganisms grow on a solid substrate. Advantages of SSF include low cost, simplicity, and high product yield. A. niger is commonly used in SSF due to its ability to produce citric acid. | ||

| 2 | ||

| LPB BC Mutant | ||

|---|---|---|

| LPB BC mutant is a genetically modified strain of A. niger. It has enhanced citric acid production capabilities compared to wild-type strains. Development of LPB BC mutant through mutagenesis and selection techniques. | ||

| 3 | ||

| Optimization of SSF Parameters | ||

|---|---|---|

| Substrate selection: Utilization of agro-industrial waste as a substrate for economical citric acid production. Moisture content: Maintaining an optimal moisture level for A. niger growth and citric acid production. pH control: Controlling the pH of the medium to promote citric acid synthesis. | ||

| 4 | ||

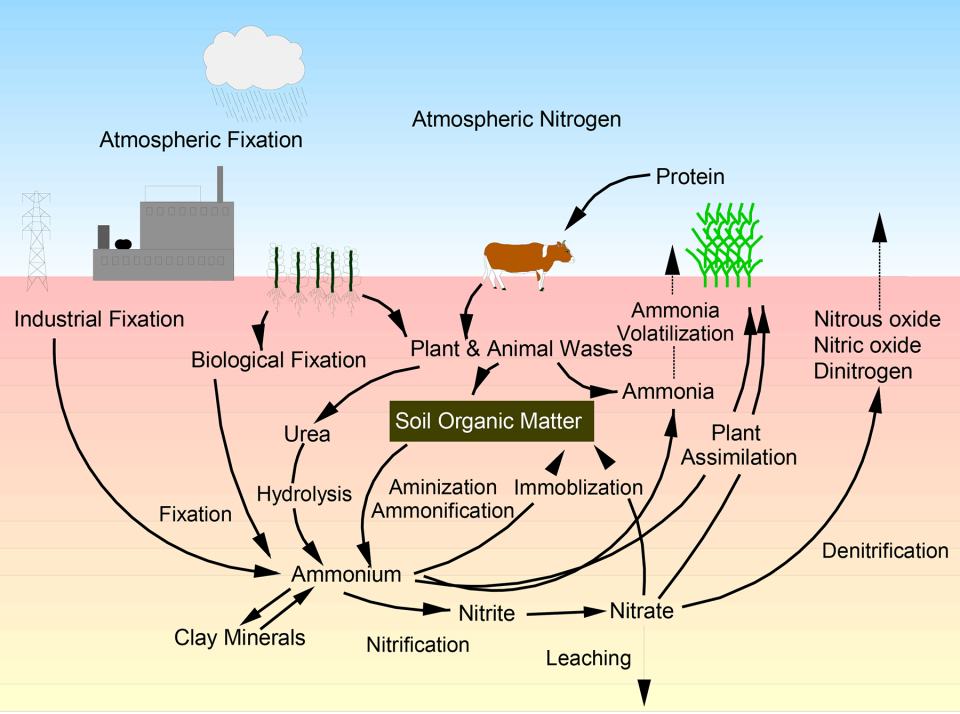

| Nutritional Requirements | ||

|---|---|---|

| Carbon source: Selecting a suitable carbon source for efficient citric acid production. Nitrogen source: Providing a balanced nitrogen source to enhance A. niger growth and citric acid production. Micronutrients: Addition of essential trace elements for optimal enzyme activity and citric acid synthesis. | ||

| 5 | ||

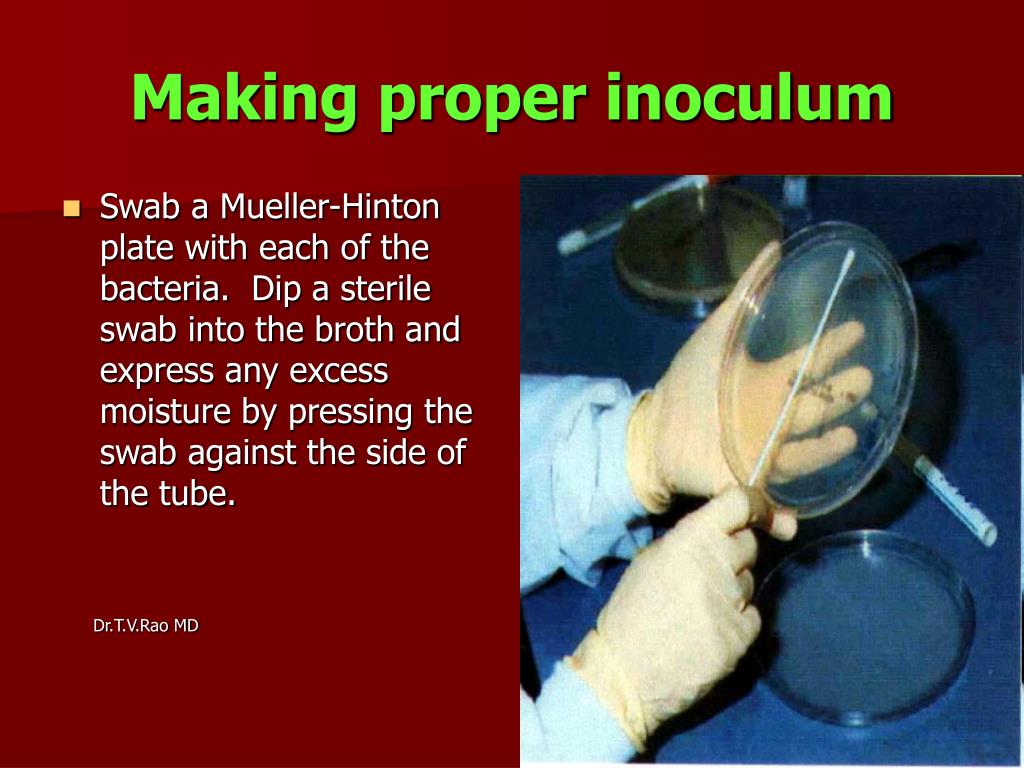

| Bioprocess Engineering | ||

|---|---|---|

| Inoculum preparation: Developing a high-quality inoculum to ensure consistent citric acid production. Temperature control: Maintaining an optimal temperature range to support A. niger growth and citric acid accumulation. Aeration and mixing: Providing adequate oxygen and efficient mixing to enhance A. niger metabolism. | ||

| 6 | ||

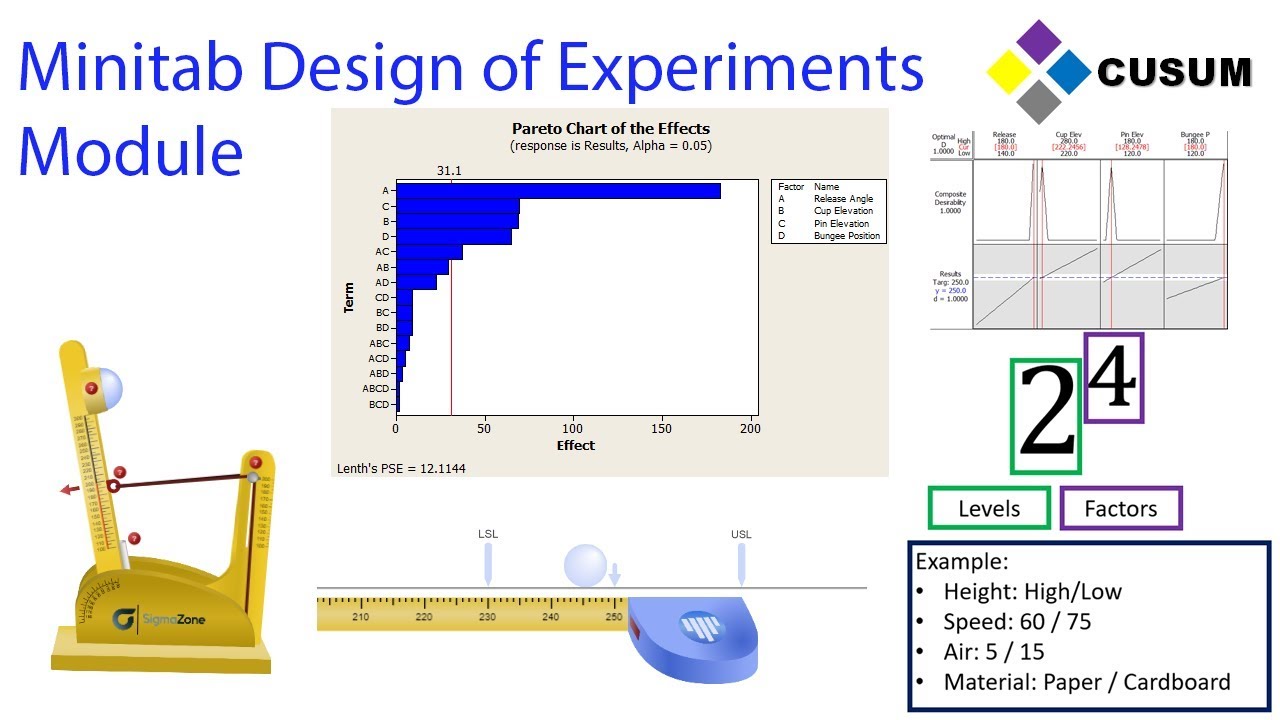

| Application of Statistical Tools | ||

|---|---|---|

| Experimental design: Utilizing statistical techniques such as Design of Experiments (DoE) to optimize process parameters. Response surface methodology (RSM): Using RSM to find the optimal combination of process variables for maximum citric acid production. Analysis of variance (ANOVA): Employing ANOVA to determine the significance of various factors on citric acid yield. | ||

| 7 | ||

| Downstream Processing | ||

|---|---|---|

| Filtration: Separating the solid substrate from the fermentation broth to recover citric acid. Concentration: Concentrating the citric acid solution through techniques like evaporation or membrane filtration. Purification: Refining the citric acid by removing impurities through techniques such as crystallization or chromatography. | ||

| 8 | ||

| Process Scale-up | ||

|---|---|---|

| Pilot-scale experiments: Conducting experiments at a larger scale to validate the process and optimize parameters. Economic analysis: Evaluating the cost-effectiveness of the improved citric acid production process. Industrial implementation: Transferring the optimized process to industrial-scale production for commercial citric acid manufacturing. | ||

| 9 | ||

| Conclusion | ||

|---|---|---|

| The improvement on citric acid production in SSF by A. niger LPB BC mutant shows promise. Optimization of process parameters, nutritional requirements, and bioprocess engineering are critical for enhanced citric acid yield. Further research and development are needed to fully exploit the potential of A. niger LPB BC mutant in industrial citric acid production. | ||

| 10 | ||