TESTING OF METAL MATRIX COMPOSITES (Al6061-ZrO2) OF DEVELOPED COMPOSITES FOR HARDNESS AND MICROSTRUC Presentation

| Introduction | ||

|---|---|---|

| Metal matrix composites (MMCs) are materials composed of a metal matrix and reinforcement particles. Al6061-ZrO2 is a widely used MMC, with aluminum (Al6061) as the matrix and Zirconia (ZrO2) as the reinforcement. Testing the hardness and microstructure of developed composites is essential for evaluating their mechanical properties. | ||

| 1 | ||

| Hardness Testing | ||

|---|---|---|

| Hardness testing measures a material's resistance to indentation or scratching. The Vickers hardness test is commonly used for MMCs, including Al6061-ZrO2 composites. A Vickers hardness tester applies a pyramid-shaped diamond indenter to the material's surface and measures the resulting indentation. | ||

| 2 | ||

| Factors Affecting Hardness | ||

|---|---|---|

| The hardness of Al6061-ZrO2 composites is influenced by various factors, including the volume fraction of ZrO2 particles. Increasing the volume fraction of ZrO2 particles generally leads to increased hardness. The distribution and size of the reinforcement particles also affect the hardness of the composites. | ||

| 3 | ||

| Microstructure Analysis | ||

|---|---|---|

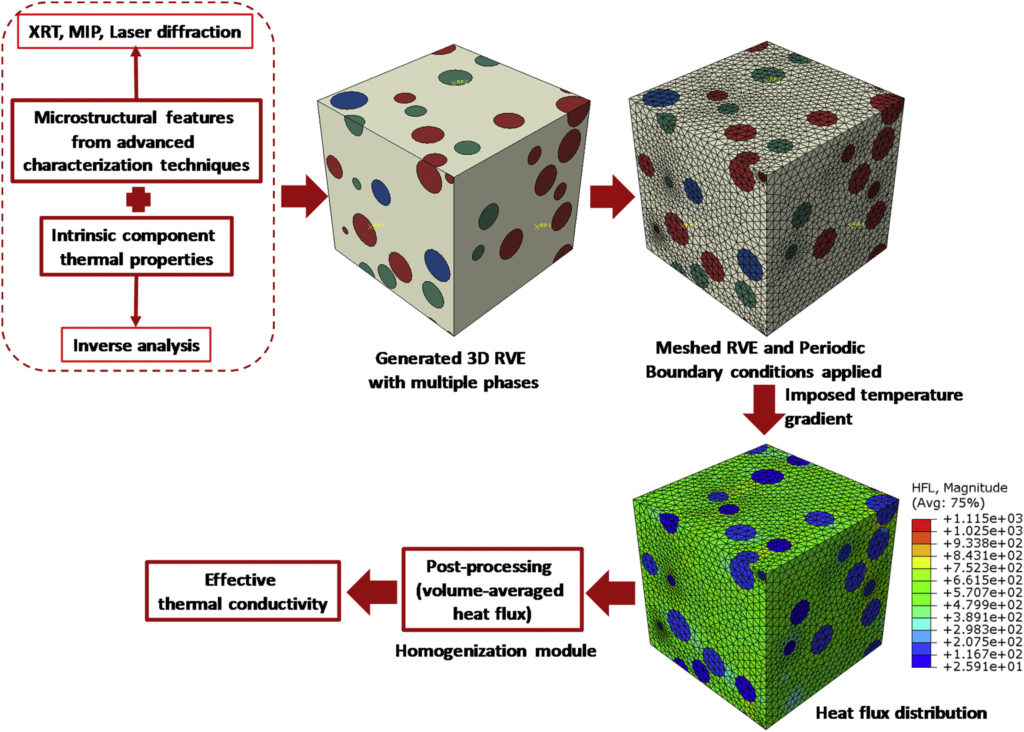

| Microstructure analysis involves studying the material's internal structure at the microscopic level. Techniques such as optical microscopy, scanning electron microscopy (SEM), and transmission electron microscopy (TEM) are commonly used. Microstructural analysis helps identify the distribution, size, and morphology of the reinforcement particles in the matrix. | ||

| 4 | ||

| Microstructure Analysis - Optical Microscopy | ||

|---|---|---|

| Optical microscopy uses visible light to observe the microstructure of materials. It provides a macroscopic view of the material's internal structure. Optical microscopy is suitable for initial characterization and identifying large-scale features. | ||

| 5 | ||

| Microstructure Analysis - Scanning Electron Microscopy (SEM) | ||

|---|---|---|

| SEM uses a focused beam of electrons to create high-resolution images of the material's surface. It provides detailed information about the topography, morphology, and distribution of particles. SEM can be coupled with energy-dispersive X-ray spectroscopy (EDS) for elemental analysis. | ||

| 6 | ||

| Microstructure Analysis - Transmission Electron Microscopy (TEM) | ||

|---|---|---|

| TEM involves transmitting electrons through a thin sample to create detailed images of the microstructure. It provides information about the crystal structure, interfaces, and defects at the atomic scale. TEM is especially useful for studying the fine details of the metal matrix and reinforcement particles. | ||

| 7 | ||

| Results and Discussion | ||

|---|---|---|

| Hardness testing and microstructure analysis of Al6061-ZrO2 composites provide valuable insights into their mechanical properties. The results can be used to optimize the composition and processing parameters of the composites. The findings also contribute to understanding the relationships between the microstructure and mechanical behavior of MMCs. | ||

| 8 | ||

| Conclusion | ||

|---|---|---|

| Testing the hardness and microstructure of developed Al6061-ZrO2 composites is crucial for evaluating their mechanical properties. Hardness testing helps assess the material's resistance to indentation or scratching. Microstructure analysis provides information about the distribution, size, and morphology of the reinforcement particles in the matrix. | ||

| 9 | ||

| Questions | ||

|---|---|---|

| Are there any questions regarding the testing of Al6061-ZrO2 composites for hardness and microstructure analysis? Your second bullet Your third bullet | ||

| 10 | ||