Properties Of Lubricant Presentation

| Introduction to Properties of Lubricant | ||

|---|---|---|

| Lubricants are substances used to reduce friction and wear between moving parts. Understanding the properties of lubricants is crucial for selecting the right lubricant for specific applications. The properties of lubricants can vary depending on their composition and intended use. | ||

| 1 | ||

| Viscosity | ||

|---|---|---|

| Viscosity is a measure of a lubricant's resistance to flow. High viscosity lubricants are thicker and provide better film strength and load-carrying capacity. Low viscosity lubricants flow more easily, offering better heat transfer and reduced drag. | ||

| 2 | ||

| Friction and Wear Reduction | ||

|---|---|---|

| Lubricants reduce friction between surfaces, minimizing wear and extending the lifespan of machinery. The ability of a lubricant to form a protective film between surfaces is crucial for reducing friction and wear. Lubricants with high film strength and anti-wear additives are preferred for heavy-duty applications. | ||

| 3 | ||

| Temperature Stability | ||

|---|---|---|

| Lubricants should maintain their properties within a wide range of temperatures. High-temperature stability prevents lubricant breakdown and maintains optimal lubrication. Low-temperature stability ensures proper lubrication even in cold environments. | ||

| 4 | ||

| Oxidation and Corrosion Resistance | ||

|---|---|---|

| Lubricants should resist oxidation, which can lead to the formation of harmful acids and sludge. Corrosion resistance is crucial to protect metal surfaces from rust and degradation. Lubricants with anti-oxidant and anti-corrosion additives provide enhanced protection. | ||

| 5 | ||

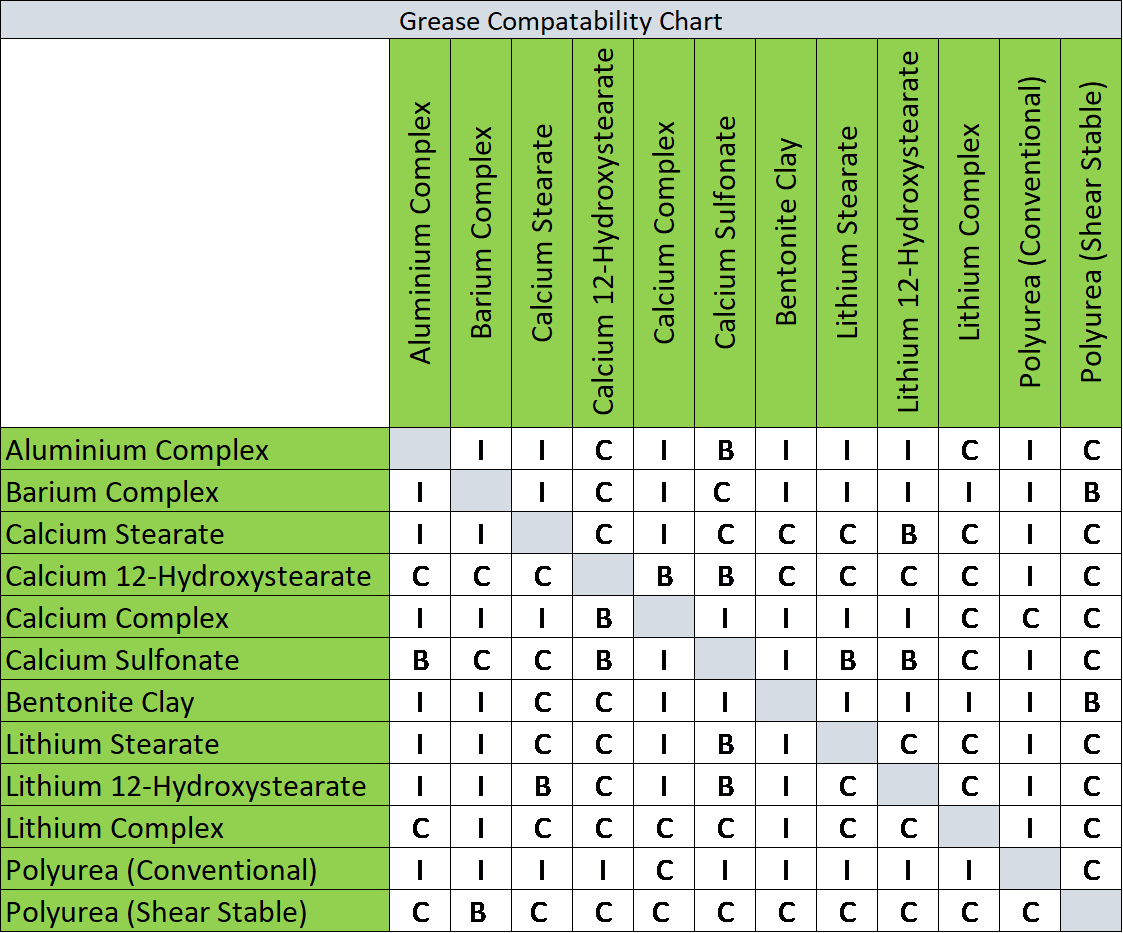

| Compatibility | ||

|---|---|---|

| Lubricants should be compatible with the materials they come into contact with. Incompatible lubricants can cause damage to seals, gaskets, and other components. Understanding the compatibility of lubricants with different materials is essential for preventing compatibility issues. | ||

| 6 | ||

| Contaminant Control | ||

|---|---|---|

| Lubricants should have excellent contaminant control properties, such as the ability to suspend and disperse contaminants. Contaminants can accelerate wear and reduce the effectiveness of lubrication. Lubricants with good filtration and anti-foaming properties help maintain clean and efficient lubrication systems. | ||

| 7 | ||

| Environmental Considerations | ||

|---|---|---|

| Lubricants should meet environmental regulations and minimize their impact on the environment. Biodegradable lubricants are preferred in environmentally sensitive areas. Proper disposal and recycling of lubricants are essential to prevent pollution. | ||

| 8 | ||

| Application-Specific Properties | ||

|---|---|---|

| Different applications require lubricants with specific properties, such as high pressure or extreme temperature resistance. Lubricants for automotive engines need to meet specific performance requirements and certifications. Understanding the application-specific properties helps in selecting the right lubricant for optimal performance. | ||

| 9 | ||

| Conclusion | ||

|---|---|---|

| The properties of lubricants, such as viscosity, friction reduction, temperature stability, and compatibility, play a crucial role in their performance. Selecting the right lubricant with the appropriate properties is essential for reducing friction, wear, and extending the lifespan of machinery. Regular lubricant analysis and maintenance ensure optimal performance and prevent costly equipment failures. | ||

| 10 | ||