Polymar Processing Presentation

| Introduction to Polymer Processing | ||

|---|---|---|

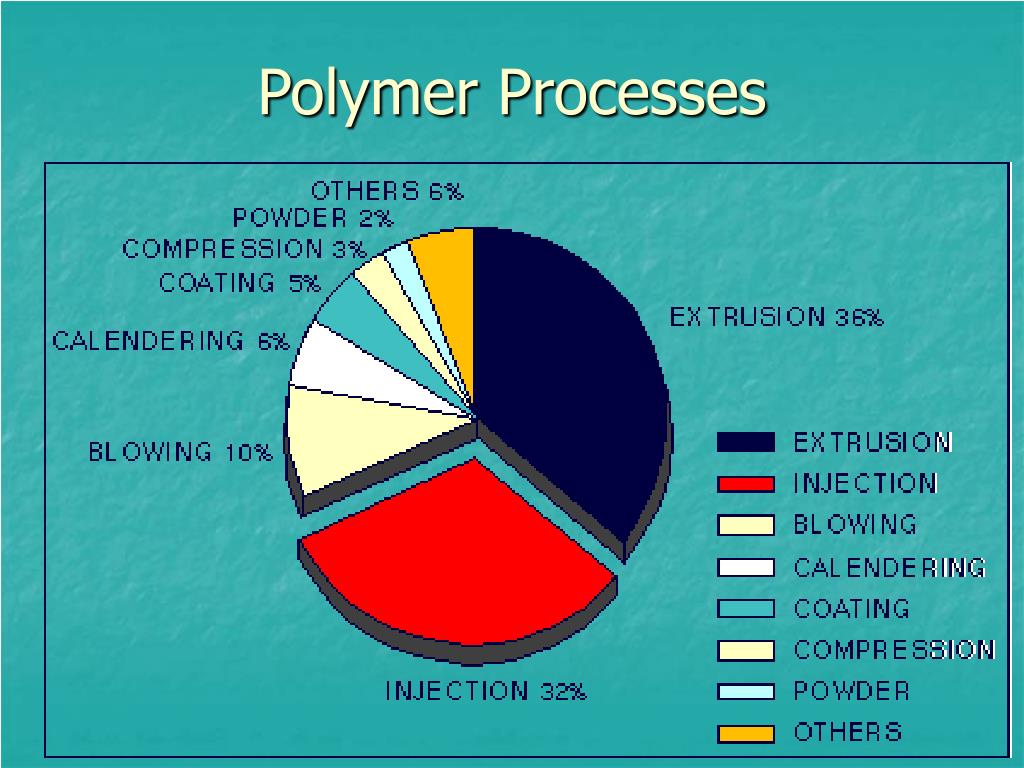

| Polymer processing is a manufacturing technique used to shape and convert polymers into useful products. It involves various methods such as extrusion, injection molding, blow molding, and thermoforming. Polymer processing plays a crucial role in industries like automotive, packaging, and electronics. | ||

| 1 | ||

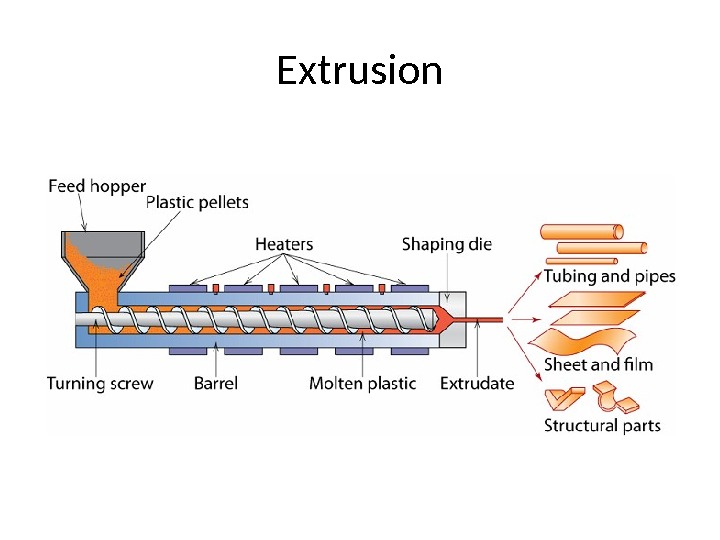

| Extrusion | ||

|---|---|---|

| Extrusion is a widely used polymer processing technique that involves forcing molten polymer through a die to create a continuous shape. It is commonly used for producing pipes, tubes, sheets, and profiles. The process can be modified to incorporate additives, fillers, or reinforcements to enhance properties. | ||

| 2 | ||

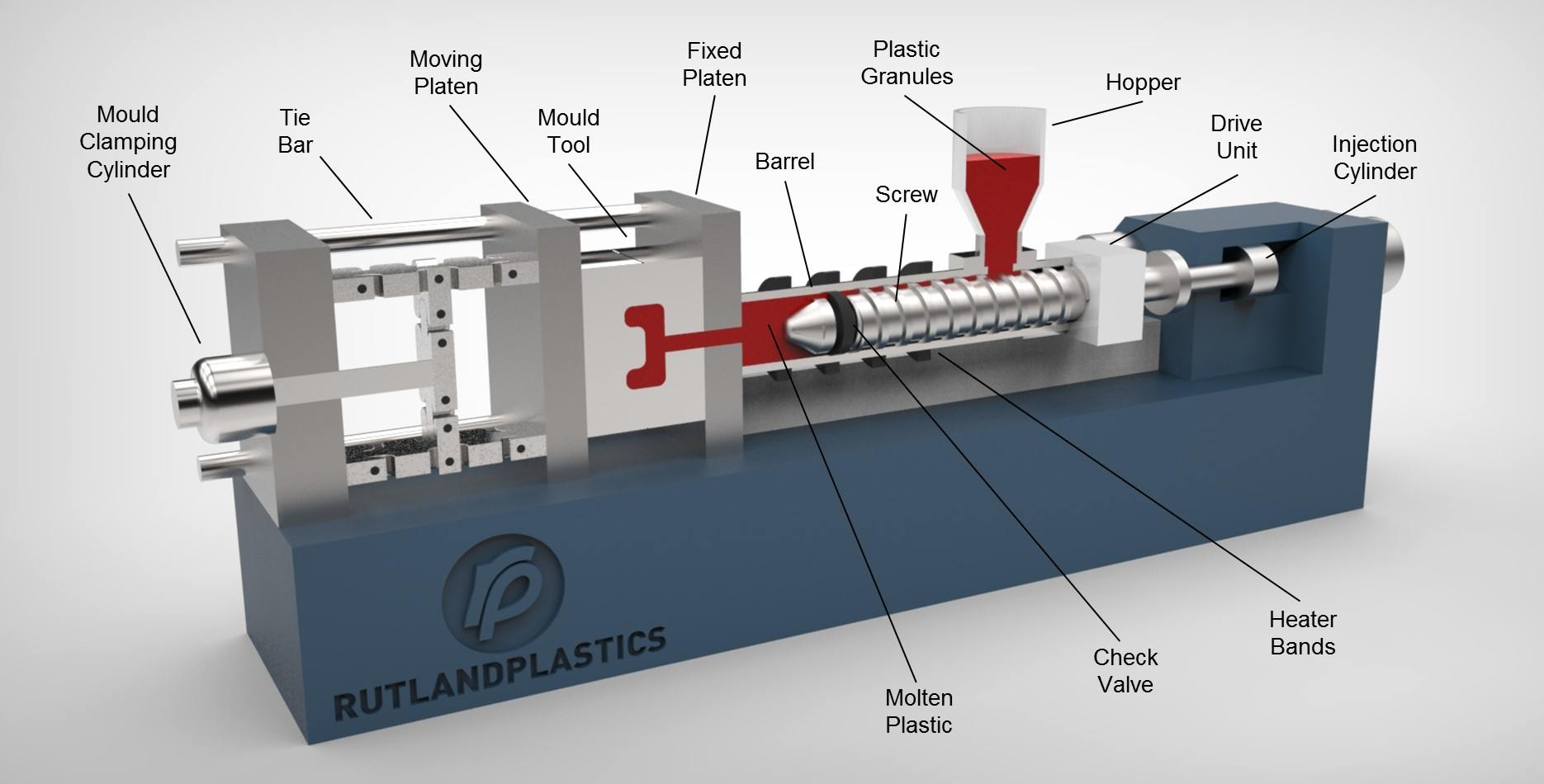

| Injection Molding | ||

|---|---|---|

| Injection molding is a versatile polymer processing technique used to produce complex and intricate shapes. It involves injecting molten polymer into a mold cavity under high pressure. Injection molding is commonly used for manufacturing automotive components, electronics, and consumer goods. | ||

| 3 | ||

| Blow Molding | ||

|---|---|---|

| Blow molding is a polymer processing technique used to create hollow objects such as bottles, containers, and tanks. The process involves inflating a heated polymer parison inside a mold cavity to obtain the desired shape. Blow molding is a cost-effective and efficient method for mass production of plastic products. | ||

| 4 | ||

| Thermoforming | ||

|---|---|---|

| Thermoforming is a polymer processing technique used to shape flat sheets into three-dimensional objects. The process involves heating the polymer sheet until it becomes pliable and then forming it over a mold using vacuum or pressure. Thermoforming is commonly used for packaging, disposable trays, and automotive interior components. | ||

| 5 | ||

| Benefits of Polymer Processing | ||

|---|---|---|

| Polymer processing allows for the production of a wide range of products with varying shapes, sizes, and properties. It enables cost-effective mass production, reducing manufacturing costs. Polymer processing techniques offer design flexibility, allowing for the creation of complex geometries and customization. | ||

| 6 | ||

| Challenges in Polymer Processing | ||

|---|---|---|

| Polymer processing involves dealing with the rheological behavior of polymers, which can be complex and temperature-dependent. Controlling melt flow, cooling rates, and shrinkage are critical challenges in achieving desired product properties. Processing parameters such as temperature, pressure, and cooling rates need to be carefully optimized for each polymer and process. | ||

| 7 | ||

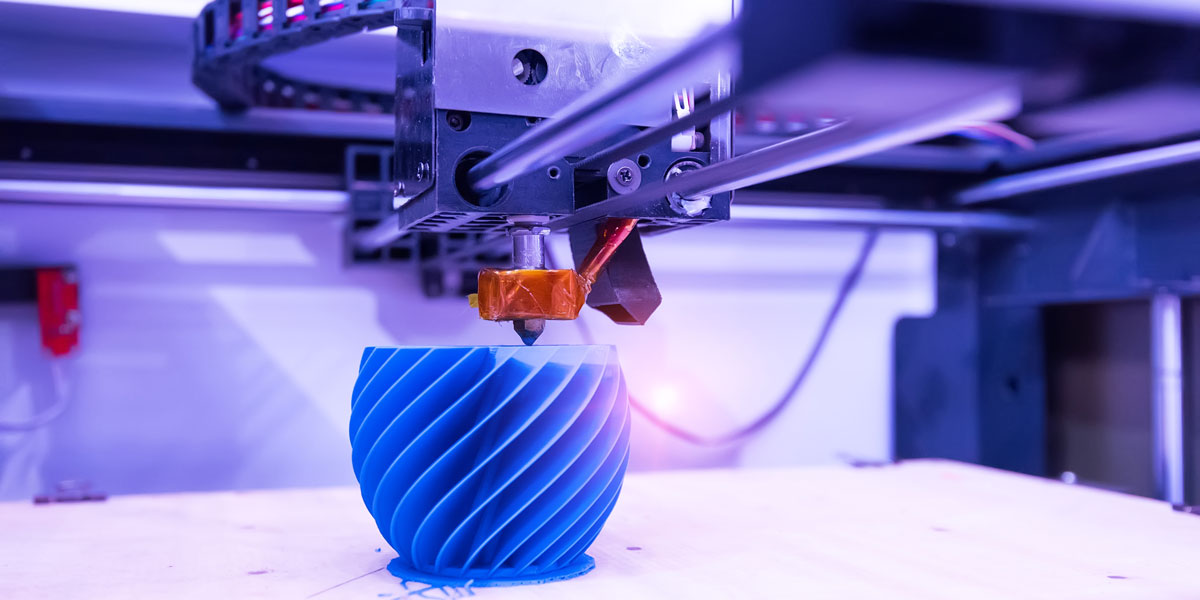

| Future Trends in Polymer Processing | ||

|---|---|---|

| Advances in additive manufacturing (3D printing) techniques offer new possibilities for polymer processing. Sustainable processing techniques such as biodegradable polymers and recycling are gaining importance. Smart polymers with self-healing, shape-memory, and conductive properties are being explored for various applications. | ||

| 8 | ||

| Applications of Polymer Processing | ||

|---|---|---|

| Automotive industry: Polymer processing is used for manufacturing interior and exterior components, fuel tanks, and lightweight materials. Packaging industry: Injection molding and blow molding are widely used for producing bottles, containers, and packaging materials. Electronics industry: Thermoforming and injection molding are utilized for manufacturing casings, connectors, and electronic components. | ||

| 9 | ||

| Conclusion | ||

|---|---|---|

| Polymer processing is a vital manufacturing technique that enables the production of a wide range of products. Different methods like extrusion, injection molding, blow molding, and thermoforming offer unique advantages. Continuous research and development in polymer processing techniques will drive innovation and shape the future of manufacturing. | ||

| 10 | ||

| References (download PPTX file for details) | ||

|---|---|---|

| Smith, J. (2018). Polymer Processing: Princip... Osswald, T. A., & Hernandez-Ortiz, J. P. (201... Harper, C. A. (2014). Handbook of Plastics, E... |  | |

| 11 | ||