Plastic Class 8 Presentation

| Introduction to Plastic Class 8 | ||

|---|---|---|

| Plastic is a synthetic material made from polymers. It is widely used in our daily lives for various purposes. Plastic Class 8 refers to a specific grade of plastic with certain characteristics. | ||

| 1 | ||

| Properties of Plastic Class 8 | ||

|---|---|---|

| Plastic Class 8 has high durability and strength. It is resistant to chemicals, water, and weather conditions. This grade of plastic has excellent electrical insulation properties. | ||

| 2 | ||

| Applications of Plastic Class 8 | ||

|---|---|---|

| Plastic Class 8 is commonly used in the automotive industry for manufacturing various components. It is used in the construction industry for making pipes, fittings, and insulation materials. This grade of plastic is also utilized in the electrical and electronics industry for producing casings and connectors. | ||

| 3 | ||

| Advantages of Plastic Class 8 | ||

|---|---|---|

| Plastic Class 8 is lightweight, making it easy to transport and handle. It is cost-effective compared to other materials. This grade of plastic is highly customizable and can be molded into various shapes and sizes. | ||

| 4 | ||

| Environmental Impact of Plastic Class 8 | ||

|---|---|---|

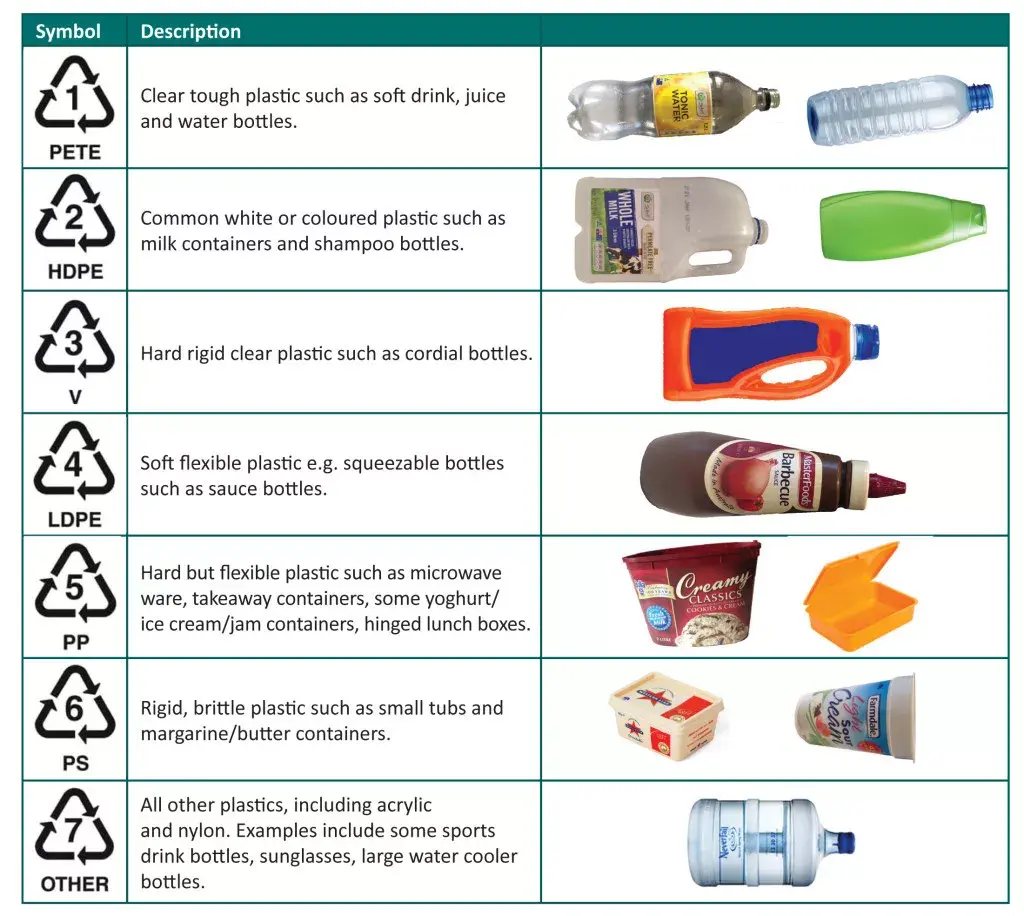

| Plastic Class 8 is non-biodegradable and can persist in the environment for hundreds of years. Improper disposal of plastic can lead to pollution of land and water bodies. Recycling and proper waste management are essential to minimize the environmental impact. | ||

| 5 | ||

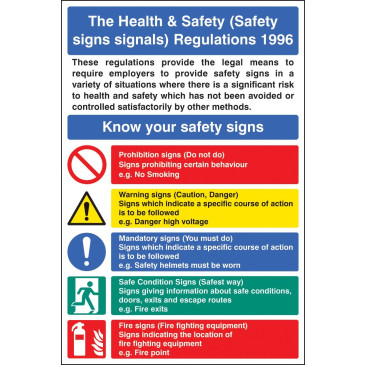

| Safety Considerations for Plastic Class 8 | ||

|---|---|---|

| It is important to handle Plastic Class 8 with proper safety precautions, such as wearing protective gloves and eyewear. Avoid exposure to high temperatures, as it can cause the plastic to melt or release harmful fumes. Store plastic materials in a dry and well-ventilated area to prevent degradation. | ||

| 6 | ||

| Standards and Regulations for Plastic Class 8 | ||

|---|---|---|

| Plastic Class 8 must comply with relevant industry standards and regulations to ensure quality and safety. Different countries may have specific guidelines for the use and manufacturing of Plastic Class 8. It is important to stay updated with the latest regulations to meet compliance requirements. | ||

| 7 | ||

| Future Trends in Plastic Class 8 | ||

|---|---|---|

| Research and development efforts are focused on making Plastic Class 8 more sustainable and environmentally friendly. Biodegradable plastic alternatives are being explored to reduce the impact on the environment. The use of recycled plastics in the production of Plastic Class 8 is gaining traction. | ||

| 8 | ||

| Challenges and Limitations of Plastic Class 8 | ||

|---|---|---|

| Plastic Class 8 is not suitable for applications that require high heat resistance. It can be prone to scratching and may require additional surface treatments for certain applications. The disposal and recycling of Plastic Class 8 can be challenging due to its long lifespan and non-biodegradable nature. | ||

| 9 | ||

| Conclusion | ||

|---|---|---|

| Plastic Class 8 is a versatile material with various applications in different industries. It offers advantages such as durability, flexibility, and cost-effectiveness. However, proper handling, waste management, and consideration of environmental impact are crucial for sustainable use of Plastic Class 8. | ||

| 10 | ||