Pallet Layout In Food Supply And Cold Chain Management Presentation

| Introduction | ||

|---|---|---|

| Pallet layout is crucial in food supply and cold chain management. Efficient pallet layout ensures proper storage and transportation of food products. Optimal pallet layout reduces damage and maintains product quality. | ||

| 1 | ||

| Importance of Pallet Layout | ||

|---|---|---|

| Proper pallet layout ensures easy loading and unloading of products. Correct layout allows for efficient space utilization in storage facilities. Well-organized pallets prevent cross-contamination and ensure food safety. | ||

| 2 | ||

| Factors to Consider in Pallet Layout | ||

|---|---|---|

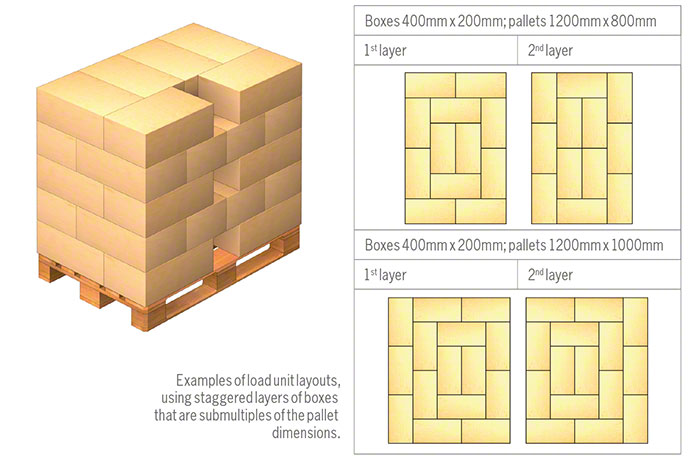

| Product characteristics, such as weight, size, and fragility, should be considered. Temperature requirements for different food items must be taken into account. Compatibility of products should be considered to prevent flavor transfer or spoilage. | ||

| 3 | ||

| Pallet Configuration Options | ||

|---|---|---|

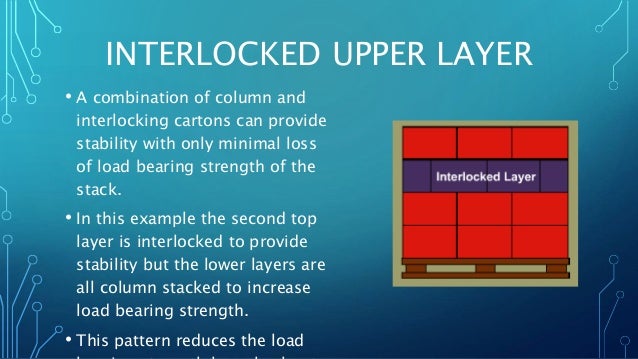

| Block stacking: Pallets are stacked directly on top of each other. Single-deep racking: Pallets are stored one deep in a racking system. Double-deep racking: Pallets are stored two deep in a racking system. | ||

| 4 | ||

| Pallet Layout Best Practices | ||

|---|---|---|

| Use standardized pallet sizes to ensure compatibility with equipment and storage systems. Place heavier and sturdier items at the bottom of the pallet to prevent damage to lighter items. Leave adequate space between pallets for proper airflow and easy access. | ||

| 5 | ||

| Cold Chain Management Considerations | ||

|---|---|---|

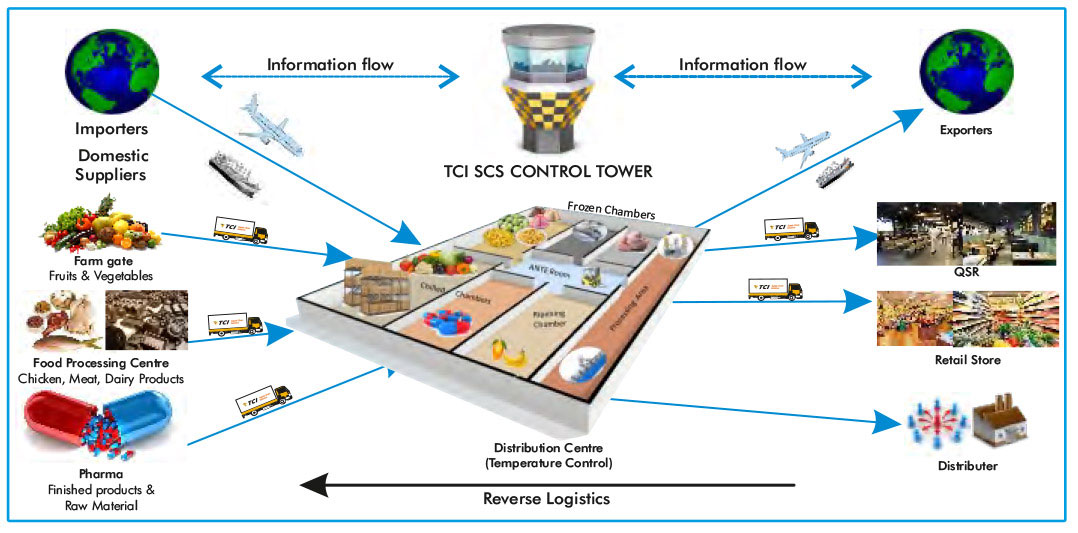

| Temperature control is crucial in preserving food quality and safety. Proper insulation and temperature monitoring equipment should be in place. Pallet layout should allow for easy access to temperature-sensitive products for monitoring and maintenance. | ||

| 6 | ||

| Pallet Layout Challenges in Cold Chain Management | ||

|---|---|---|

| Limited space in refrigerated storage facilities may require creative pallet layout solutions. Managing multiple temperature zones within the same facility can be challenging. Maintaining proper airflow and temperature distribution with densely packed pallets can be difficult. | ||

| 7 | ||

| Technology and Innovation in Pallet Layout | ||

|---|---|---|

| Automated palletizing systems optimize pallet layout and reduce labor costs. RFID tags and sensors enable real-time tracking and monitoring of pallets and product conditions. Simulation software helps determine the most efficient pallet layout for specific products and storage conditions. | ||

| 8 | ||

| Benefits of Proper Pallet Layout | ||

|---|---|---|

| Minimizes product damage and loss during storage and transportation. Optimizes space utilization, reducing storage costs. Enhances overall efficiency and productivity in the cold chain management process. | ||

| 9 | ||

| Conclusion | ||

|---|---|---|

| Pallet layout plays a vital role in food supply and cold chain management. Proper layout ensures product integrity, reduces costs, and improves efficiency. Adopting best practices and leveraging technology can lead to significant benefits in the food industry. | ||

| 10 | ||