Oriented System Architecture For Feature-Based Data Management In CNC Machining Processes Presentation

| Introduction | ||

|---|---|---|

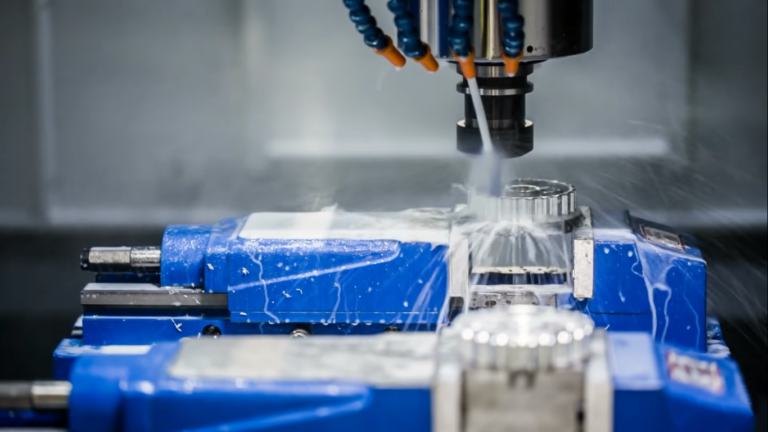

| Oriented System Architecture for Feature-Based Data Management in CNC Machining Processes is a crucial aspect of modern manufacturing. Feature-based data management refers to the organization and storage of data based on specific features of a product or component. CNC machining processes involve the use of computer numerical control to automate machine tools for efficient and precise manufacturing. | ||

| 1 | ||

| Benefits of Feature-Based Data Management | ||

|---|---|---|

| Feature-based data management allows for better collaboration between different stakeholders in the manufacturing process. It enables effective reuse of design and manufacturing data, reducing redundancy and saving time. Feature-based data management facilitates the automation of CNC machining processes, resulting in increased productivity and reduced errors. | ||

| 2 | ||

| Key Components of Oriented System Architecture | ||

|---|---|---|

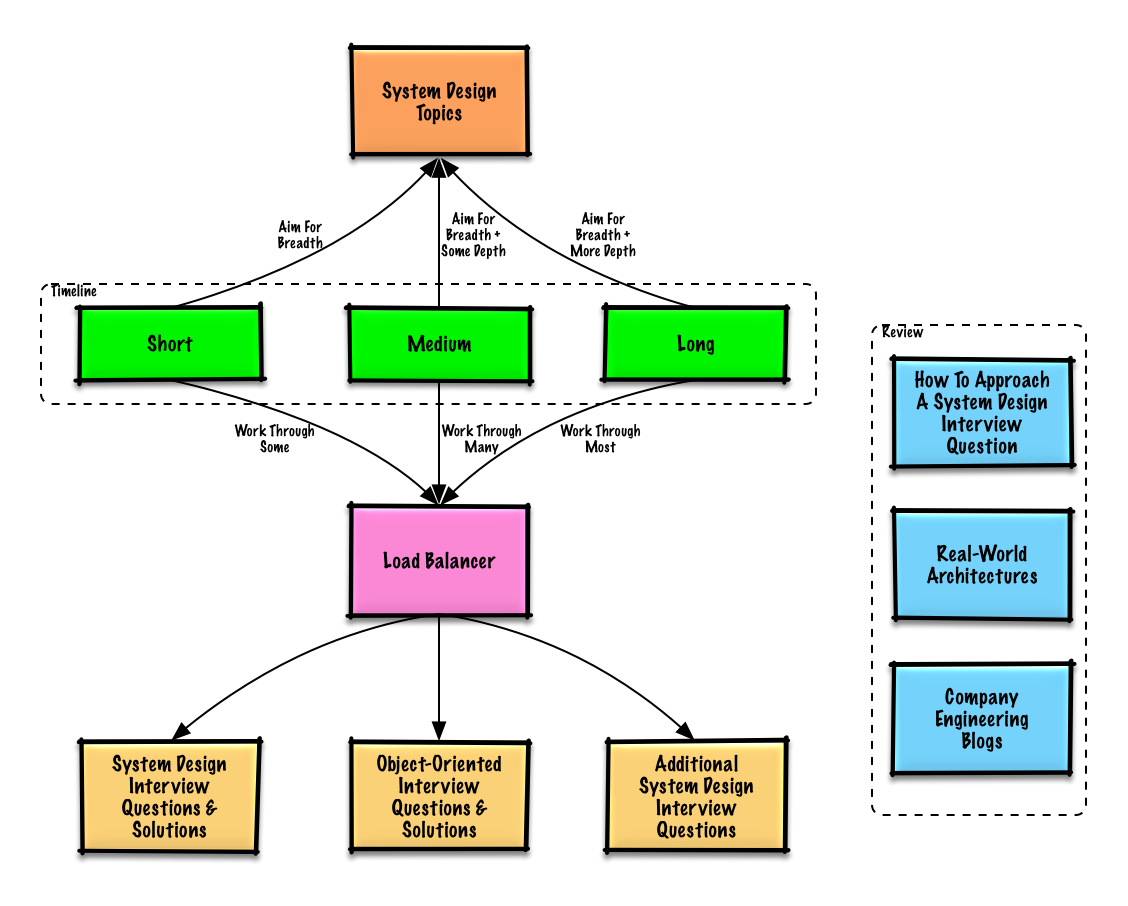

| The oriented system architecture for feature-based data management consists of three main components: feature recognition, feature-based modeling, and process planning. Feature recognition involves automatically identifying and extracting geometric features from CAD models. Feature-based modeling allows for the creation and manipulation of features as individual entities, enabling better design and manufacturing flexibility. | ||

| 3 | ||

| Feature Recognition | ||

|---|---|---|

| Feature recognition utilizes algorithms to analyze CAD models and identify geometric features such as holes, pockets, and fillets. It plays a crucial role in automating the programming of CNC machines, as it eliminates the need for manual programming of each individual feature. Feature recognition enhances the accuracy and consistency of machining operations by ensuring that all relevant features are accounted for. | ||

| 4 | ||

| Feature-Based Modeling | ||

|---|---|---|

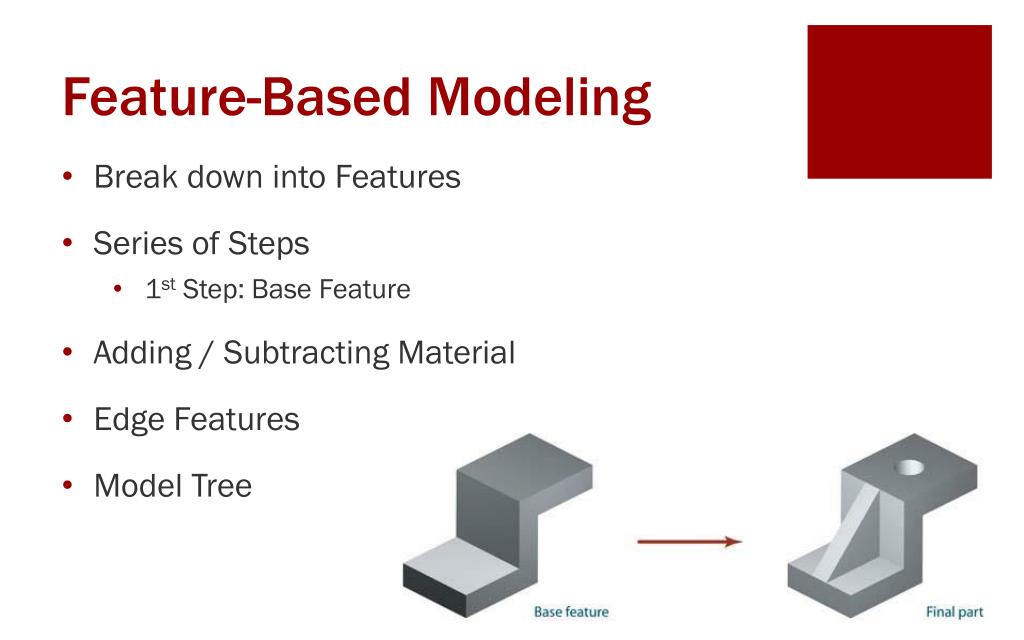

| Feature-based modeling allows for the creation and management of features as independent entities within the CAD system. It enables designers to easily modify and manipulate features, providing greater design flexibility. Feature-based modeling also facilitates the integration of design and manufacturing data, ensuring that changes in design are reflected in the machining process. | ||

| 5 | ||

| Process Planning | ||

|---|---|---|

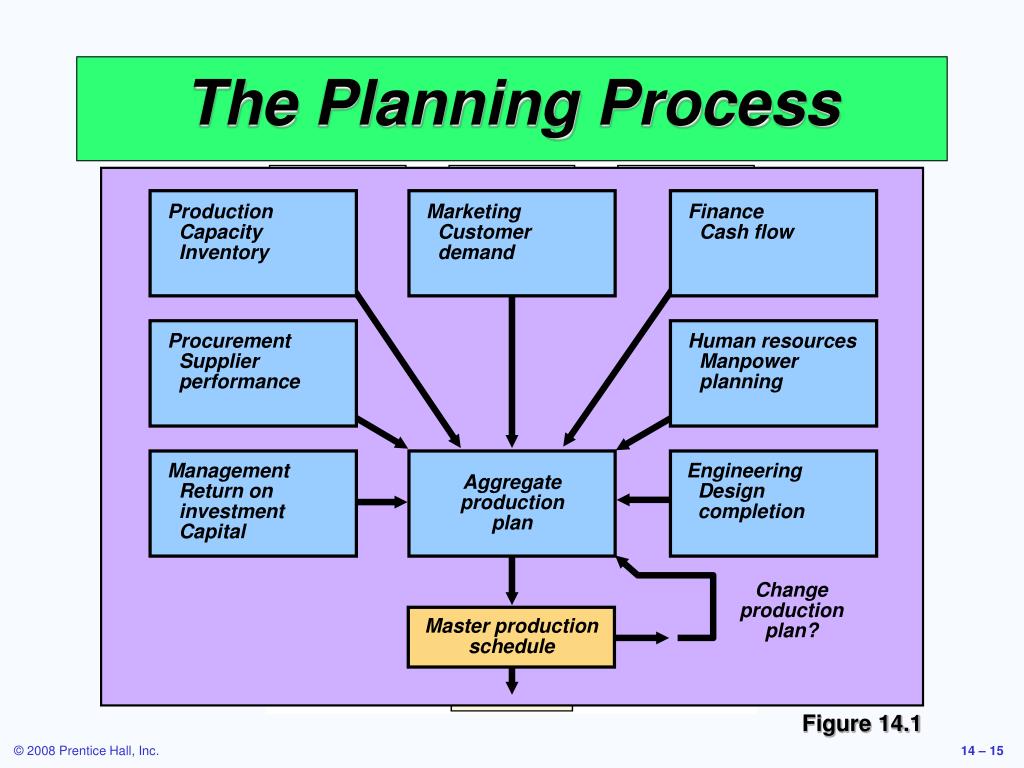

| Process planning involves determining the optimal sequence of machining operations for a given set of features. It takes into account factors such as tool selection, cutting parameters, and machining constraints. Process planning ensures that the manufacturing process is efficient, cost-effective, and capable of producing high-quality parts. | ||

| 6 | ||

| Integration and Interoperability | ||

|---|---|---|

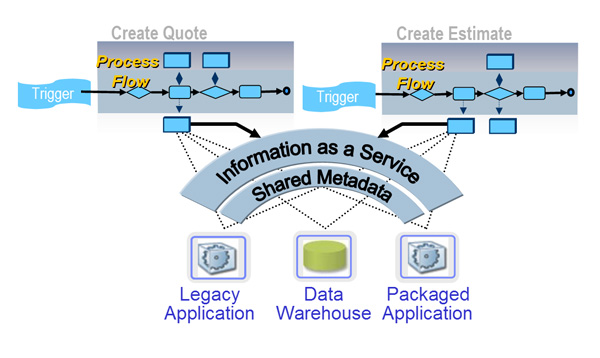

| Oriented system architecture for feature-based data management requires seamless integration and interoperability between various software systems. Integration allows for the transfer of data between CAD/ CAM, feature recognition, and process planning systems. Interoperability ensures that data can be exchanged and used across different software systems without loss of fidelity or functionality. | ||

| 7 | ||

| Challenges and Future Directions | ||

|---|---|---|

| One of the key challenges in feature-based data management is the standardization of feature definitions and classifications. Future directions in this field include the development of advanced feature recognition algorithms and the integration of artificial intelligence techniques. The adoption of cloud-based platforms and web services can also enhance collaboration and data sharing in feature-based data management. | ||

| 8 | ||

| Case Studies and Success Stories | ||

|---|---|---|

| Several companies have successfully implemented feature-based data management in their CNC machining processes, resulting in significant improvements in productivity and quality. Case studies highlight the benefits of feature-based data management in reducing lead times, improving design iterations, and enabling efficient process planning. Success stories demonstrate how feature-based data management has revolutionized CNC machining processes, leading to cost savings and competitive advantages. |  | |

| 9 | ||

| Conclusion | ||

|---|---|---|

| Oriented system architecture for feature-based data management is a critical enabler for efficient and effective CNC machining processes. It allows for better collaboration, reuse of data, and automation, leading to improved productivity and quality. Continued advancements in feature recognition, modeling, and process planning will further enhance the capabilities and benefits of this architecture. | ||

| 10 | ||

| References (download PPTX file for details) | ||

|---|---|---|

| Author Last Name, Initials. (Year). Title of ... Author Last Name, Initials. (Year). Title of ... Author Last Name, Initials. (Year). Title of ... |  | |

| 11 | ||