Multiple Effect Evaporator Presentation

| Introduction to Multiple Effect Evaporator | ||

|---|---|---|

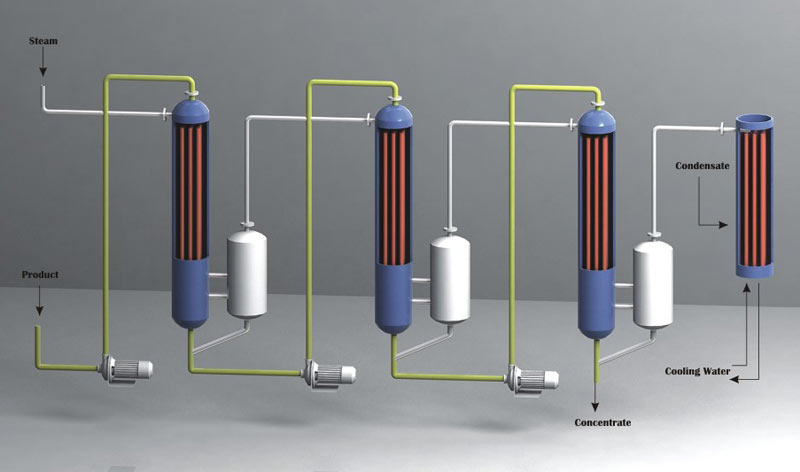

| Multiple effect evaporator is a type of evaporator system used in various industries for the concentration of liquid solutions. It consists of a series of evaporators, known as effects, where each effect operates at a progressively lower pressure and temperature than the previous one. The heat from the high-pressure steam generated in the first effect is used to evaporate the liquid in the following effects, resulting in energy efficiency. | ||

| 1 | ||

| Advantages of Multiple Effect Evaporator | ||

|---|---|---|

| Energy efficiency: Multiple effect evaporators can save significant amounts of energy by utilizing the heat from the steam in each effect to drive the evaporation process in subsequent effects. Increased production capacity: The use of multiple effects allows for a higher evaporation rate, resulting in increased production capacity compared to single effect evaporators. Cost-effectiveness: The energy savings achieved by multiple effect evaporators can lead to reduced operating costs in the long run, making it a cost-effective solution for industries. |  | |

| 2 | ||

| Applications of Multiple Effect Evaporator | ||

|---|---|---|

| Food and beverage industry: Multiple effect evaporators are commonly used in the food and beverage industry for concentration of fruit juices, dairy products, and other liquid food products. Chemical industry: Multiple effect evaporators are utilized in the chemical industry for concentration of various chemical solutions, such as acids, solvents, and pharmaceutical intermediates. Desalination: Multiple effect evaporators can also be employed in desalination processes, where they help in removing the water content from seawater or brackish water to obtain fresh water. Note: Remember to include relevant images or diagrams to support the information on each slide. |  | |

| 3 | ||