Mechanism Of Lubrications (thick Film) Presentation

| Introduction | ||

|---|---|---|

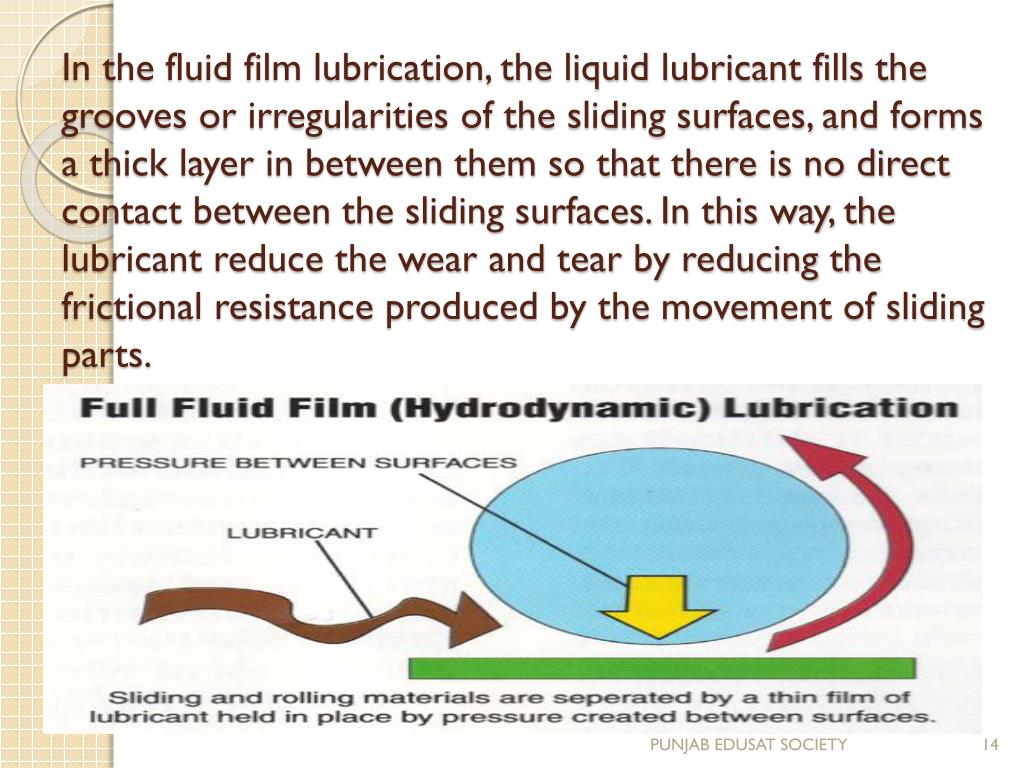

| Lubrication is essential in reducing friction and wear between moving surfaces. Thick Film Lubrication is a mechanism that involves the formation of a thick layer of lubricant between surfaces. It provides superior load-carrying capacity and is commonly used in heavy-duty applications. | ||

| 1 | ||

| Types of Thick Film Lubrication | ||

|---|---|---|

| Hydrodynamic Lubrication: Occurs when a fluid film is formed due to the relative motion between surfaces. Elastohydrodynamic Lubrication (EHL): Involves the deformation of lubricant and surfaces under high loads. Squeeze Film Lubrication: Occurs when the lubricant is squeezed between surfaces due to external forces. | ||

| 2 | ||

| Mechanism of Hydrodynamic Lubrication | ||

|---|---|---|

| The relative motion between surfaces causes a pressure gradient in the lubricant. This pressure gradient generates a hydrodynamic wedge, lifting the surfaces apart. The lubricant film thickness should be greater than the surface roughness to prevent metal-to-metal contact. | ||

| 3 | ||

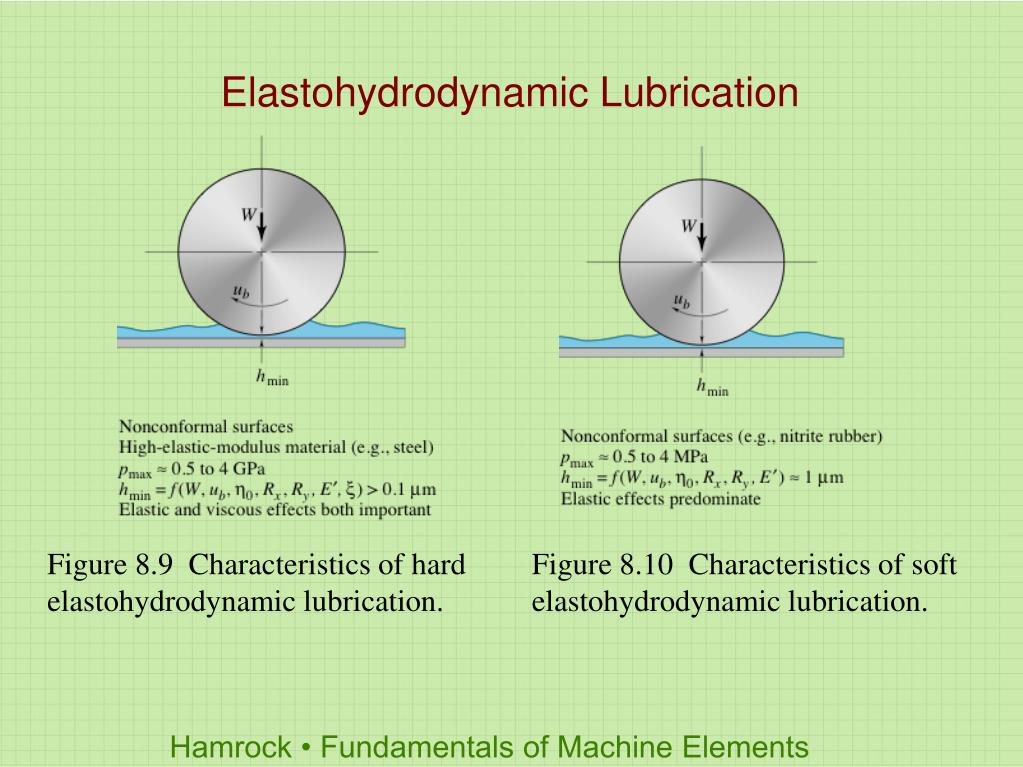

| Mechanism of Elastohydrodynamic Lubrication (EHL) | ||

|---|---|---|

| EHL occurs under high loads and high speeds where the lubricant experiences severe deformation. The lubricant forms a pressurized film between the surfaces, preventing direct contact. The lubricant viscosity and elasticity play a crucial role in sustaining the film. | ||

| 4 | ||

| Mechanism of Squeeze Film Lubrication | ||

|---|---|---|

| Squeeze film lubrication occurs when external forces compress the lubricant between surfaces. The lubricant acts as a cushion, absorbing and distributing the load evenly. It is commonly used in journal bearings and thrust bearings. | ||

| 5 | ||

| Benefits of Thick Film Lubrication | ||

|---|---|---|

| Reduction in friction and wear between moving surfaces. Increased load-carrying capacity, allowing for higher load applications. Improved protection against surface damage and corrosion. | ||

| 6 | ||

| Factors Affecting Thick Film Lubrication | ||

|---|---|---|

| Lubricant viscosity: Higher viscosity provides a thicker film for better lubrication. Surface roughness: Smoother surfaces reduce the risk of metal-to-metal contact. Operating temperature: Extreme temperatures can affect the lubricant's viscosity and performance. | ||

| 7 | ||

| Applications of Thick Film Lubrication | ||

|---|---|---|

| Heavy machinery and equipment, such as engines, turbines, and gearboxes. Automotive industry for engine and transmission components. Industrial applications, including steel mills, paper mills, and power plants. | ||

| 8 | ||

| Maintenance and Considerations | ||

|---|---|---|

| Regular lubricant analysis to ensure proper viscosity and contamination levels. Periodic checks of lubricant film thickness and surface condition. Adequate lubricant replenishment and filtration to maintain optimal performance. | ||

| 9 | ||

| Conclusion | ||

|---|---|---|

| Thick Film Lubrication is a crucial mechanism in reducing friction and wear between moving surfaces. It provides superior load-carrying capacity and protection against surface damage. Understanding the mechanism and factors influencing thick film lubrication is essential for proper maintenance and application. | ||

| 10 | ||