Heat Exchanger And Second Order Derivation And Applications Presentation

| Introduction to Heat Exchanger and Second Order Derivation | ||

|---|---|---|

| Heat exchangers are devices used to transfer heat between two or more fluids, without the fluids mixing. They are widely used in various industries such as power plants, chemical processing, refrigeration, and HVAC systems. Second order derivation is a mathematical technique used to analyze the performance and efficiency of heat exchangers. | ||

| 1 | ||

| Types of Heat Exchangers | ||

|---|---|---|

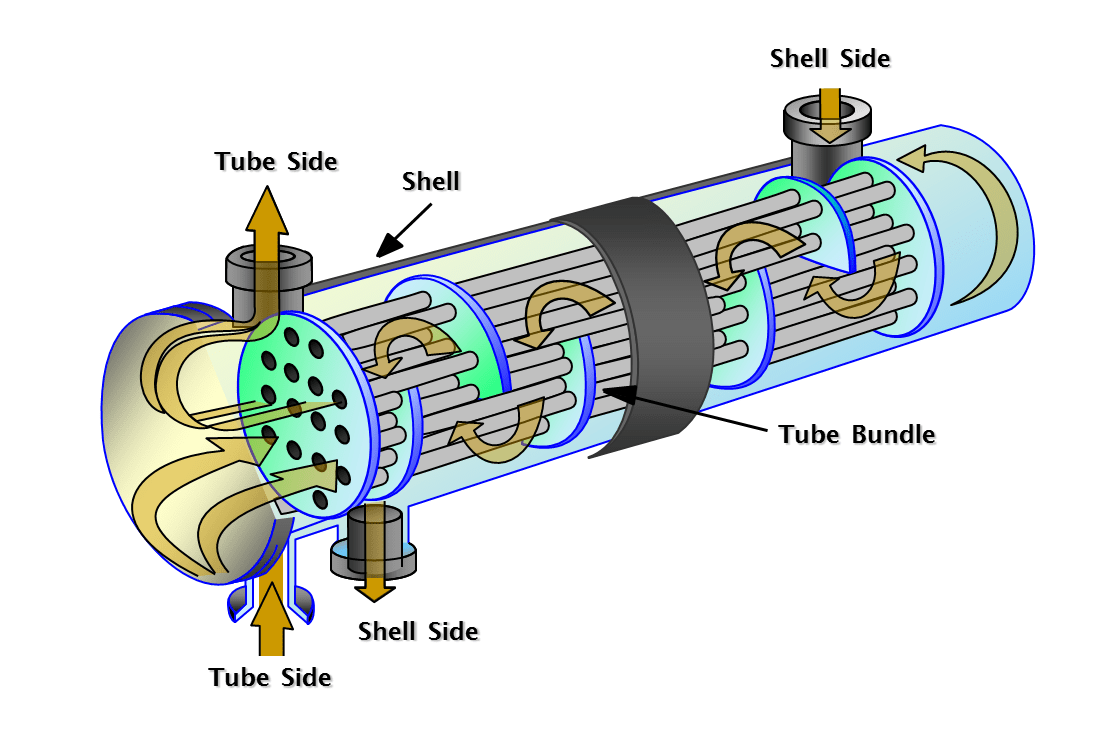

| Shell and tube heat exchangers: Consist of a shell filled with tubes, allowing one fluid to flow through the tubes while the other flows over the tubes. Plate heat exchangers: Comprised of stacked plates with alternating hot and cold fluid channels, promoting efficient heat transfer. Finned tube heat exchangers: Features extended surfaces (fins) on the tubes to increase heat transfer surface area. | ||

| 2 | ||

| Heat Exchanger Design Considerations | ||

|---|---|---|

| Heat transfer area: Determined by the heat duty, temperature difference between fluids, and overall heat transfer coefficient. Fluid flow arrangement: Parallel flow, counterflow, or crossflow configurations affect the heat transfer efficiency. Material selection: Consider factors such as corrosion resistance, thermal conductivity, and pressure limitations. | ||

| 3 | ||

| Second Order Derivation Basics | ||

|---|---|---|

| Second order derivation involves analyzing the performance of heat exchangers using mathematical equations. It helps determine parameters such as heat transfer rate, effectiveness, overall heat transfer coefficient, and pressure drop. Equations derived from second order derivation are used to optimize heat exchanger designs and improve efficiency. | ||

| 4 | ||

| Heat Exchanger Effectiveness | ||

|---|---|---|

| Effectiveness is a measure of how efficiently a heat exchanger transfers heat. It is calculated as the ratio of actual heat transfer to the maximum possible heat transfer. High effectiveness indicates a more efficient heat exchanger design. | ||

| 5 | ||

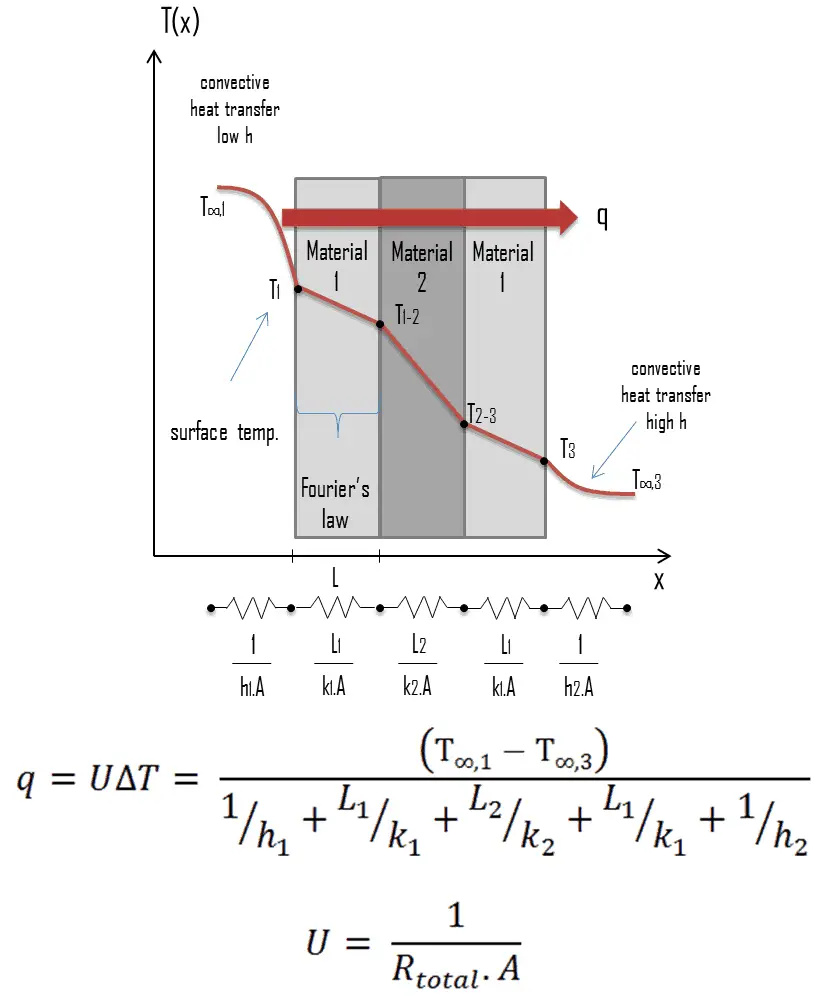

| Overall Heat Transfer Coefficient (U) | ||

|---|---|---|

| The overall heat transfer coefficient represents the thermal resistance of a heat exchanger. It is a combination of the individual resistances of the fluids, tube walls, and fouling. Higher U values indicate better heat transfer performance. | ||

| 6 | ||

| Pressure Drop in Heat Exchangers | ||

|---|---|---|

| Pressure drop refers to the decrease in fluid pressure as it flows through a heat exchanger. It is influenced by factors such as fluid velocity, flow arrangement, and heat exchanger geometry. Optimal pressure drop allows for efficient heat transfer without excessive energy consumption. | ||

| 7 | ||

| Applications of Heat Exchangers | ||

|---|---|---|

| Power plants: Heat exchangers are used to transfer heat from the combustion gases to water or steam in boilers. Refrigeration systems: Heat exchangers are essential components in air conditioning units and refrigeration cycles. Chemical processing: Heat exchangers facilitate heat transfer in various chemical reactions and separation processes. | ||

| 8 | ||

| Industrial Applications of Heat Exchangers | ||

|---|---|---|

| Oil and gas industry: Heat exchangers are used for crude oil cooling, natural gas processing, and heat recovery. Food and beverage industry: Heat exchangers play a crucial role in pasteurization, sterilization, and product cooling. Automotive industry: Heat exchangers are essential in engine cooling systems and HVAC units. | ||

| 9 | ||

| Conclusion | ||

|---|---|---|

| Heat exchangers are vital in various industries for efficient heat transfer between fluids. Second order derivation enables the analysis and optimization of heat exchanger designs. Understanding heat exchanger principles and applications is crucial for enhancing energy efficiency. | ||

| 10 | ||

| References (download PPTX file for details) | ||

|---|---|---|

| [Insert reference 1]... [Insert reference 2]... [Insert reference 3]... |  | |

| 11 | ||