Digital Light Processing In 3d Printing Presentation

| Introduction to Digital Light Processing (DLP) in 3D Printing | ||

|---|---|---|

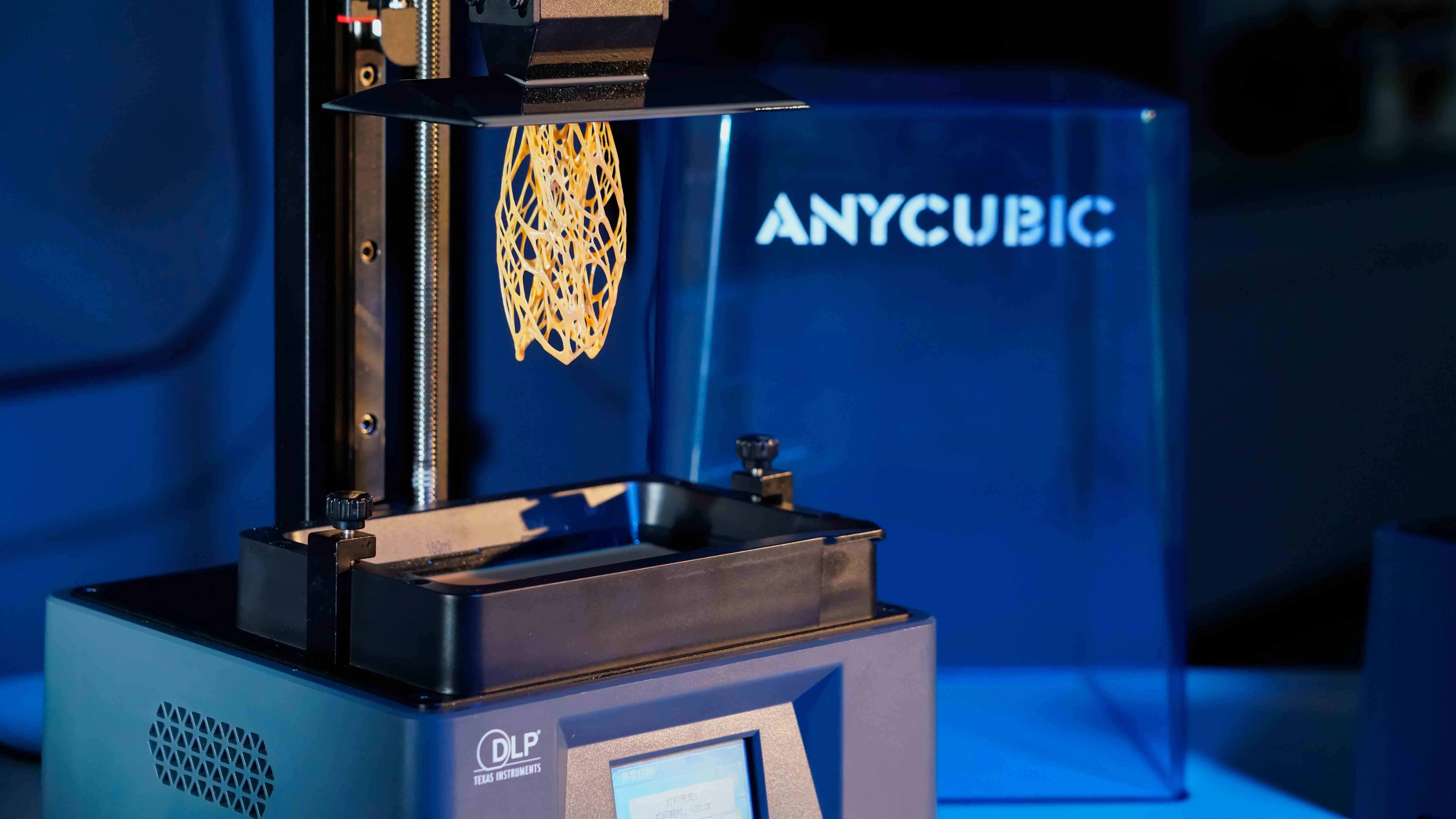

| Digital Light Processing (DLP) is a 3D printing technology that uses photopolymerization to create objects layer by layer. DLP printers use a digital light projector to cure liquid resin, turning it into solid objects. DLP offers high resolution and faster printing speeds compared to other 3D printing technologies. | ||

| 1 | ||

| How DLP 3D Printing Works | ||

|---|---|---|

| DLP 3D printers use a vat of liquid resin, which is cured by a light source. The light source, usually an array of UV LEDs or a digital projector, emits light in the form of patterns or images. The light patterns selectively cure the resin, solidifying it to form each layer of the object. | ||

| 2 | ||

| Advantages of DLP 3D Printing | ||

|---|---|---|

| DLP offers high printing speeds due to its ability to cure entire layers at once, rather than sequentially. DLP printers can achieve high levels of detail and accuracy, producing smooth and precise objects. The use of liquid resin allows for a wide range of material properties, from flexible to rigid, and even transparent. | ||

| 3 | ||

| Applications of DLP 3D Printing | ||

|---|---|---|

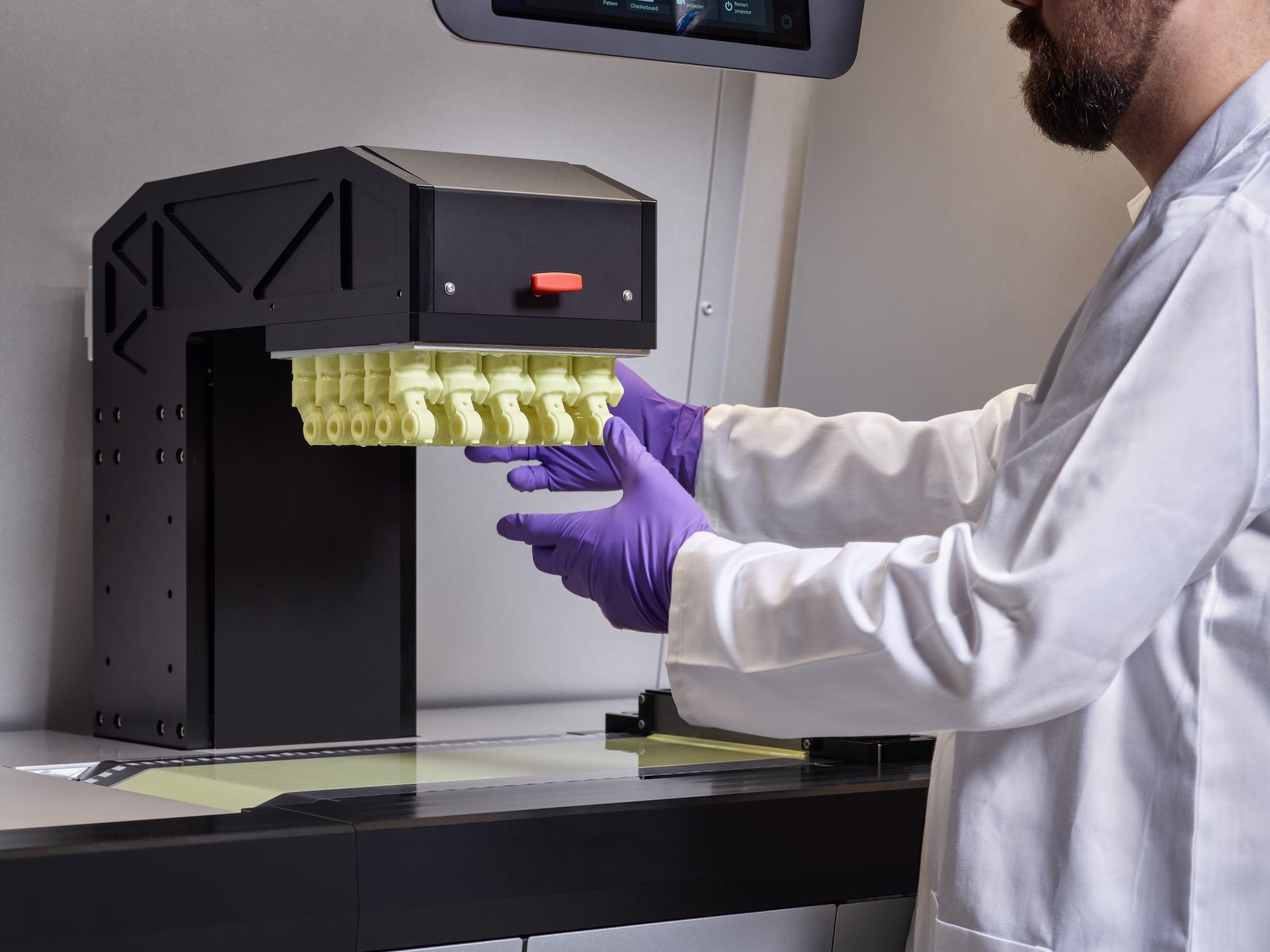

| DLP is widely used in industries such as dentistry, jewelry, and prototyping. In dentistry, DLP is used to create dental models, aligners, and surgical guides with high precision. Jewelry designers utilize DLP to create intricate and detailed pieces, reducing the need for traditional casting processes. | ||

| 4 | ||

| Challenges of DLP 3D Printing | ||

|---|---|---|

| One challenge is the limited range of materials available for DLP printing compared to other 3D printing technologies. The layer-by-layer curing process can result in visible layer lines on the printed object, requiring post-processing to achieve a smooth finish. DLP printers can be expensive, making them less accessible for individual users or small businesses. | ||

| 5 | ||

| Future Developments in DLP 3D Printing | ||

|---|---|---|

| Researchers are exploring new materials and formulations to expand the range of properties available for DLP printing. Advancements in projector technology may lead to higher resolution and faster curing speeds. Integration of DLP with other technologies, such as multi-material printing or hybrid additive-subtractive processes, may further enhance its capabilities. | ||

| 6 | ||

| Conclusion | ||

|---|---|---|

| DLP 3D printing offers high-resolution printing and fast production speeds, making it suitable for various industries. Despite some challenges, ongoing research and development are expected to further improve DLP technology. As the technology evolves, DLP 3D printing has the potential to revolutionize manufacturing and enable new possibilities in design and production. | ||

| 7 | ||

| Thank You! | ||

|---|---|---|

| Thank you for your attention! Please feel free to ask any questions. Your second bullet Your third bullet | ||

| 8 | ||