Dc Motor Working Process Presentation

| Introduction to DC Motor Working Process | ||

|---|---|---|

| A DC motor is an electrical device that converts electrical energy into mechanical energy. It operates based on the principle of electromagnetic induction. DC motors are widely used in various applications such as robotics, industrial machinery, and automotive systems. | ||

| 1 | ||

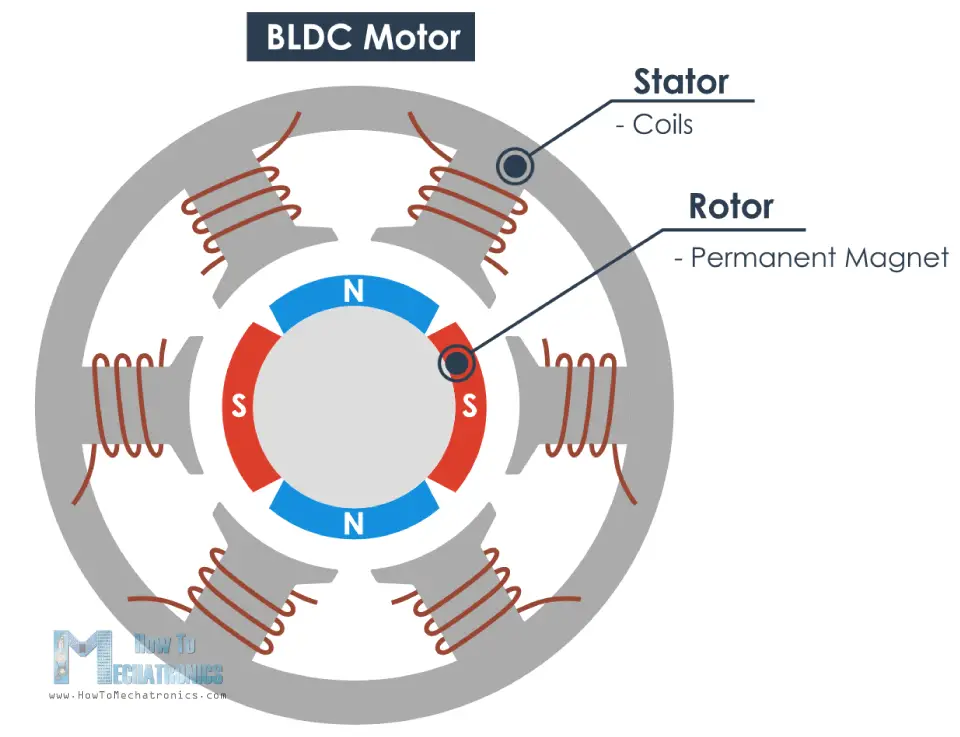

| Basic Components of a DC Motor | ||

|---|---|---|

| The main components of a DC motor include a stator, rotor, commutator, and brushes. The stator is the stationary part of the motor that houses the field magnets. The rotor is the rotating part of the motor that contains the armature and the commutator. | ||

| 2 | ||

| Working Principle of a DC Motor | ||

|---|---|---|

| When an electric current flows through the armature, it creates a magnetic field. The magnetic field interacts with the field magnets, causing a torque that rotates the rotor. The commutator and brushes ensure the continuous flow of current in the armature, which maintains the rotation. | ||

| 3 | ||

| Types of DC Motors | ||

|---|---|---|

| There are several types of DC motors, including brushed motors, brushless motors, and stepper motors. Brushed motors use brushes and commutators to control the flow of current. Brushless motors use electronic controllers to control the current flow, eliminating the need for brushes. | ||

| 4 | ||

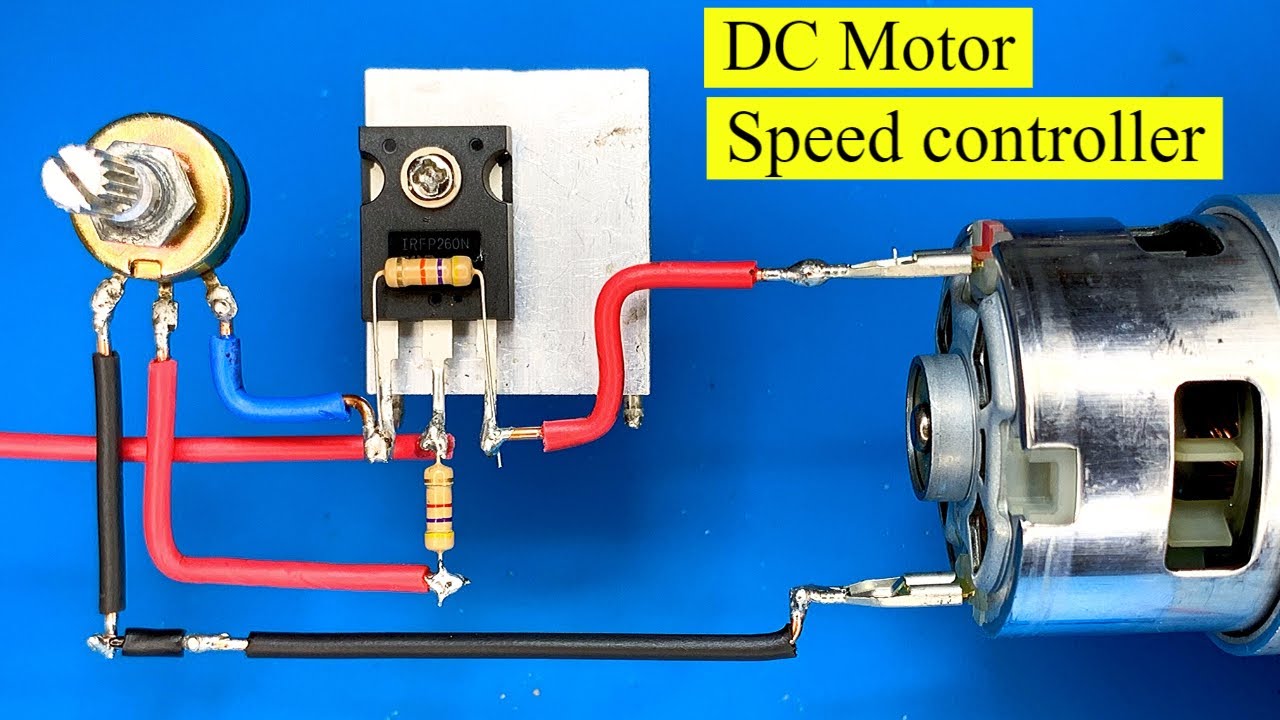

| DC Motor Speed Control | ||

|---|---|---|

| The speed of a DC motor can be controlled by varying the input voltage or by adjusting the field current. Increasing the voltage increases the speed, while reducing the voltage decreases the speed. By changing the field current, the magnetic field strength can be adjusted, affecting the motor's speed. | ||

| 5 | ||

| DC Motor Efficiency | ||

|---|---|---|

| DC motors are known for their high efficiency, typically ranging from 70% to 90%. The efficiency is influenced by factors such as motor design, quality of materials, and operating conditions. Proper maintenance, lubrication, and regular inspection can help maintain and improve motor efficiency. | ||

| 6 | ||

| Advantages of DC Motors | ||

|---|---|---|

| DC motors offer high torque and speed control capabilities. They have a simple and robust construction, making them reliable and durable. DC motors are cost-effective and readily available in various sizes and power ratings. | ||

| 7 | ||

| Limitations of DC Motors | ||

|---|---|---|

| DC motors require regular maintenance, including brush replacement and commutator cleaning. They produce electromagnetic interference (EMI) that can interfere with nearby electronic equipment. DC motors have limited efficiency at low speeds and may require additional control mechanisms for precise speed control. | ||

| 8 | ||

| Applications of DC Motors | ||

|---|---|---|

| DC motors find applications in various industries, including automotive, aerospace, robotics, and manufacturing. They are used in electric vehicles, fans, pumps, conveyor systems, and machine tools. DC motors are also commonly used in household appliances such as refrigerators, air conditioners, and washing machines. | ||

| 9 | ||

| Conclusion | ||

|---|---|---|

| DC motors are versatile and widely used for converting electrical energy into mechanical energy. Understanding the working process and components of DC motors is essential for their efficient operation. Continuous advancements in motor technology continue to enhance the performance and efficiency of DC motors. | ||

| 10 | ||

| References (download PPTX file for details) | ||

|---|---|---|

| Reference 1: "DC Motor... Working Principle, Types, and Applications." ... Reference 2: "How Does a DC Motor Work?" By S... |  | |

| 11 | ||