Dairy Manufacturing Risk Measurements And Perils And Hazards Presentation

| Introduction to Dairy Manufacturing Risk Measurements and Perils and Hazards | ||

|---|---|---|

| Dairy manufacturing involves various risks that can impact the safety and quality of dairy products. Risk measurements are essential in identifying and assessing potential perils and hazards. Understanding and managing these risks are crucial for ensuring consumer safety and maintaining business reputation. | ||

| 1 | ||

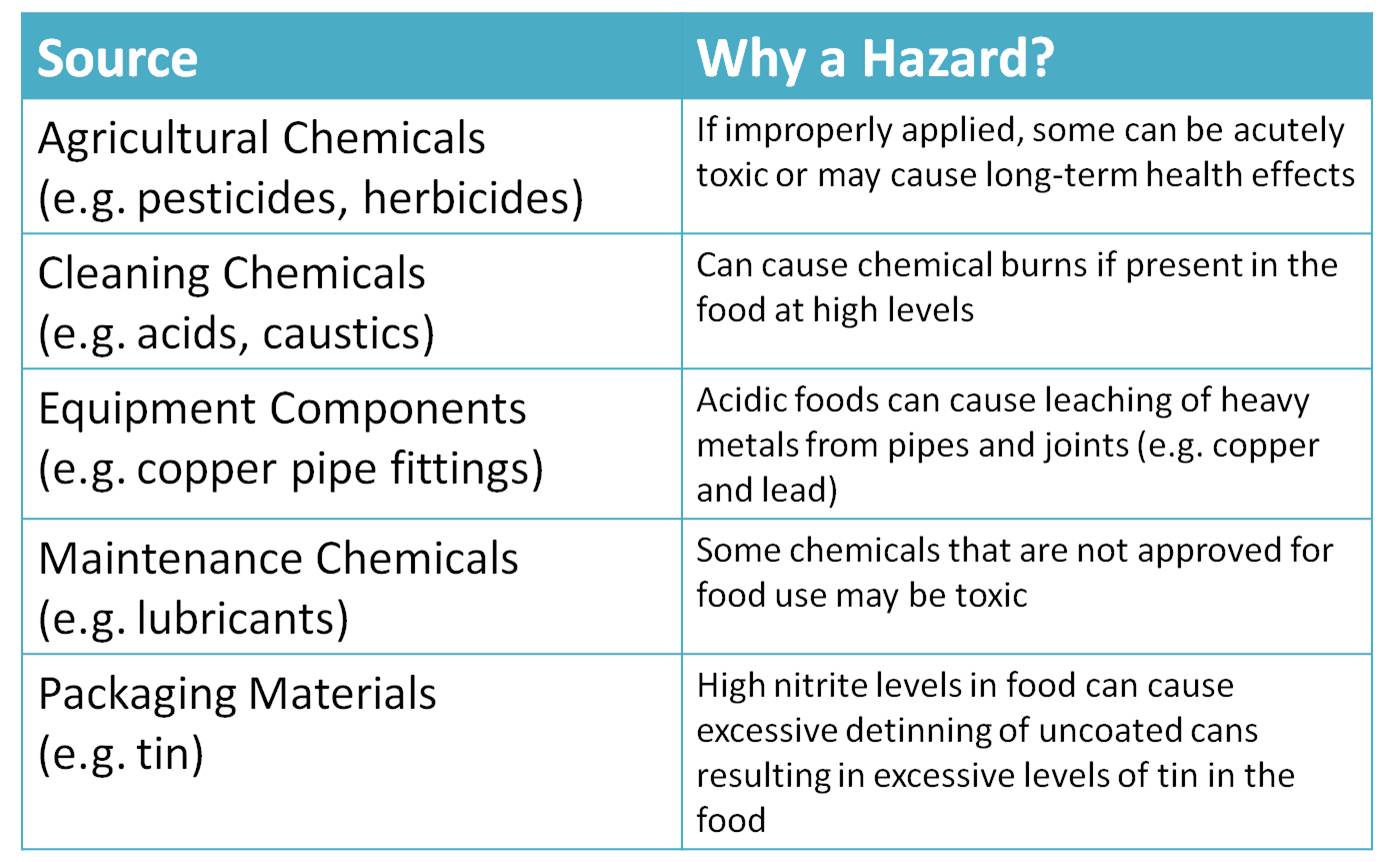

| Types of Risks in Dairy Manufacturing | ||

|---|---|---|

| Biological risks, such as contamination by pathogens like Salmonella or E.coli, can lead to foodborne illnesses. Chemical risks, like the presence of antibiotics or pesticides in milk, can pose health hazards. Physical risks, such as foreign objects or contaminants in dairy products, can cause injuries or choking hazards. | ||

| 2 | ||

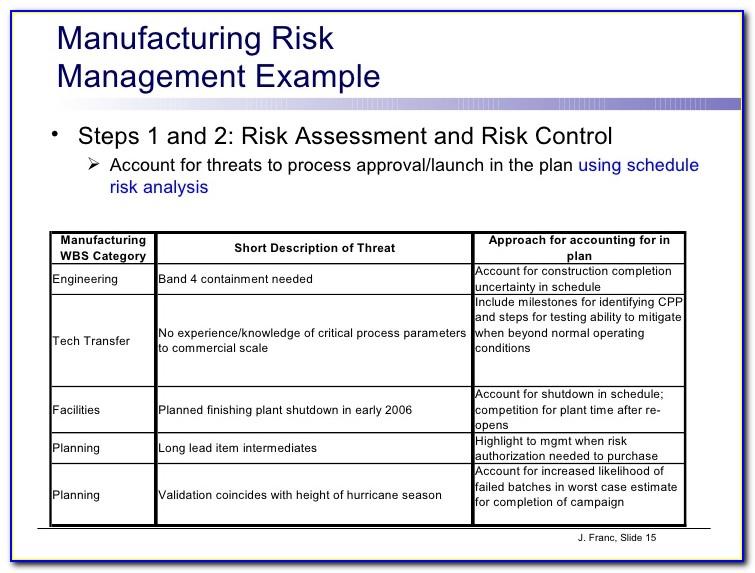

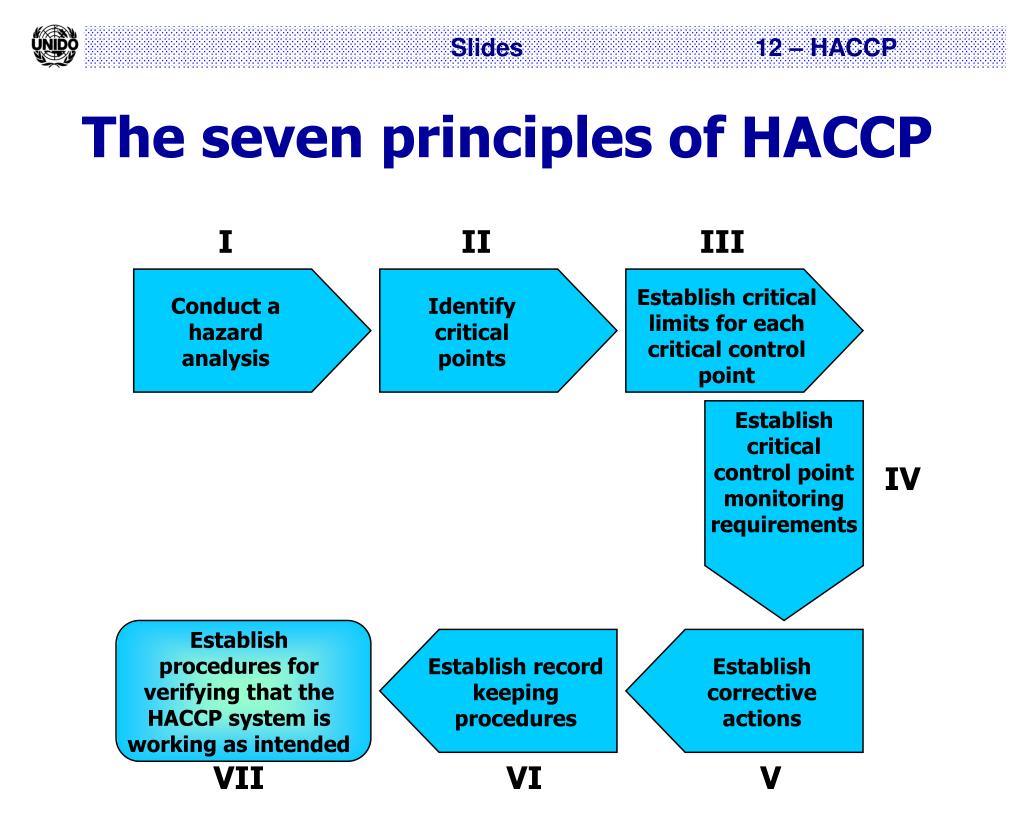

| Risk Measurements in Dairy Manufacturing | ||

|---|---|---|

| Hazard Analysis and Critical Control Points (HACCP) is a systematic approach to identify and control hazards throughout the production process. Microbiological testing is conducted to monitor the presence of harmful bacteria and ensure compliance with safety standards. Regular inspections and audits help assess risk levels and identify areas for improvement in hygiene and sanitation practices. | ||

| 3 | ||

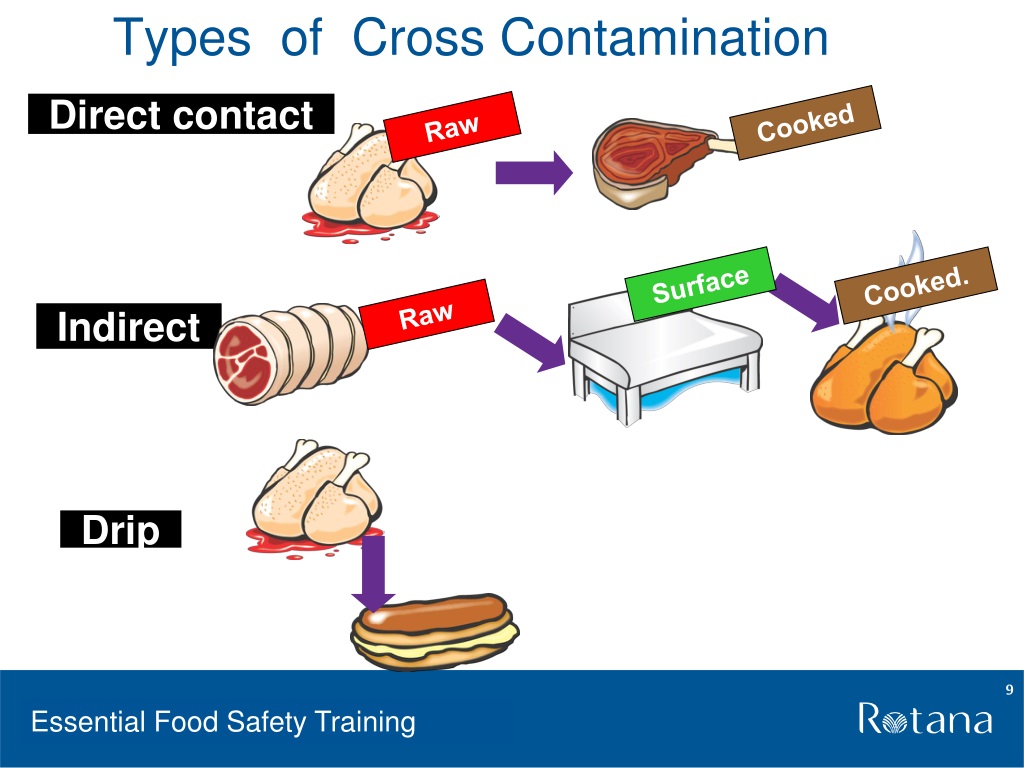

| Perils in Dairy Manufacturing | ||

|---|---|---|

| Cross-contamination of raw and processed products can occur during handling, processing, or storage, leading to microbial contamination. Insufficient pasteurization or improper temperature control can result in the survival of pathogens, jeopardizing product safety. Inadequate cleaning and sanitization practices can contribute to the growth of bacteria, fungi, and biofilms, increasing the risk of contamination. | ||

| 4 | ||

| Hazards in Dairy Manufacturing | ||

|---|---|---|

| Equipment malfunction or failure can lead to product contamination, physical hazards, or process deviations. Improper labeling or packaging can result in misidentification, allergen cross-contact, or tampering risks. Inadequate training and employee hygiene practices can introduce risks of personal contamination and foodborne illnesses. | ||

| 5 | ||

| Risk Mitigation Strategies | ||

|---|---|---|

| Implementing Good Manufacturing Practices (GMP) ensures proper hygiene, sanitation, and maintenance procedures are followed. Applying preventive maintenance programs for equipment and machinery reduces the risk of failures and contamination. Conducting regular employee training and enforcing strict hygiene protocols minimizes the potential for personal contamination. | ||

| 6 | ||

| Regulatory Compliance | ||

|---|---|---|

| Dairy manufacturers must adhere to local and international regulations and standards, such as the Food Safety Modernization Act (FSMA) in the United States. Compliance with regulatory requirements helps ensure consumer safety and prevents legal repercussions. Regular audits and inspections by regulatory bodies help identify non-compliance issues and provide opportunities for corrective actions. | ||

| 7 | ||

| Continuous Improvement and Risk Assessment | ||

|---|---|---|

| Ongoing risk assessment and continuous improvement are vital for maintaining high safety standards in dairy manufacturing. Regularly reviewing and updating risk management strategies help address emerging risks and industry advancements. Collaborating with industry peers, experts, and regulatory agencies facilitates knowledge sharing and best practice adoption. | ||

| 8 | ||

| Case Studies | ||

|---|---|---|

| Case study 1: Contamination of dairy products due to inadequate cleaning procedures and improper storage conditions. Case study 2: Outbreak of foodborne illnesses linked to the presence of pathogens in raw milk due to insufficient pasteurization. Case study 3: Product recall and reputational damage caused by mislabeled allergens in dairy products. | ||

| 9 | ||

| Conclusion | ||

|---|---|---|

| Dairy manufacturing risk measurements and the identification of perils and hazards are crucial for ensuring product safety and customer satisfaction. Implementing effective risk mitigation strategies and complying with regulatory requirements are essential for business success. Continuous improvement and collaboration within the industry are key to managing emerging risks and maintaining high standards in dairy manufacturing. | ||

| 10 | ||