Cost Minimization Strategyies In Production Presentation

| Introduction | ||

|---|---|---|

| Cost minimization strategies in production are essential for businesses to stay competitive in the market. By implementing these strategies, companies can optimize their production processes and reduce expenses. In this presentation, we will explore various cost minimization strategies that can be applied in production. | ||

| 1 | ||

| Efficient Resource Allocation | ||

|---|---|---|

| Efficient resource allocation involves identifying and utilizing resources effectively to minimize costs. By analyzing production processes and identifying bottlenecks, companies can allocate resources optimally. Implementing lean manufacturing techniques can help eliminate waste and increase productivity, leading to cost reductions. | ||

| 2 | ||

| Automation and Technology | ||

|---|---|---|

| Automation and technology can significantly reduce production costs by increasing efficiency and productivity. By automating repetitive tasks, companies can save on labor costs and minimize errors. Adopting advanced technologies, such as robotics or artificial intelligence, can enhance production processes and lead to cost savings. | ||

| 3 | ||

| Supplier Relationship Management | ||

|---|---|---|

| Building strong relationships with suppliers can result in cost minimization. Negotiating favorable terms, bulk purchasing, and long-term contracts can lead to discounts and lower production costs. Collaborating with suppliers to streamline the supply chain and reduce lead times can also result in cost savings. | ||

| 4 | ||

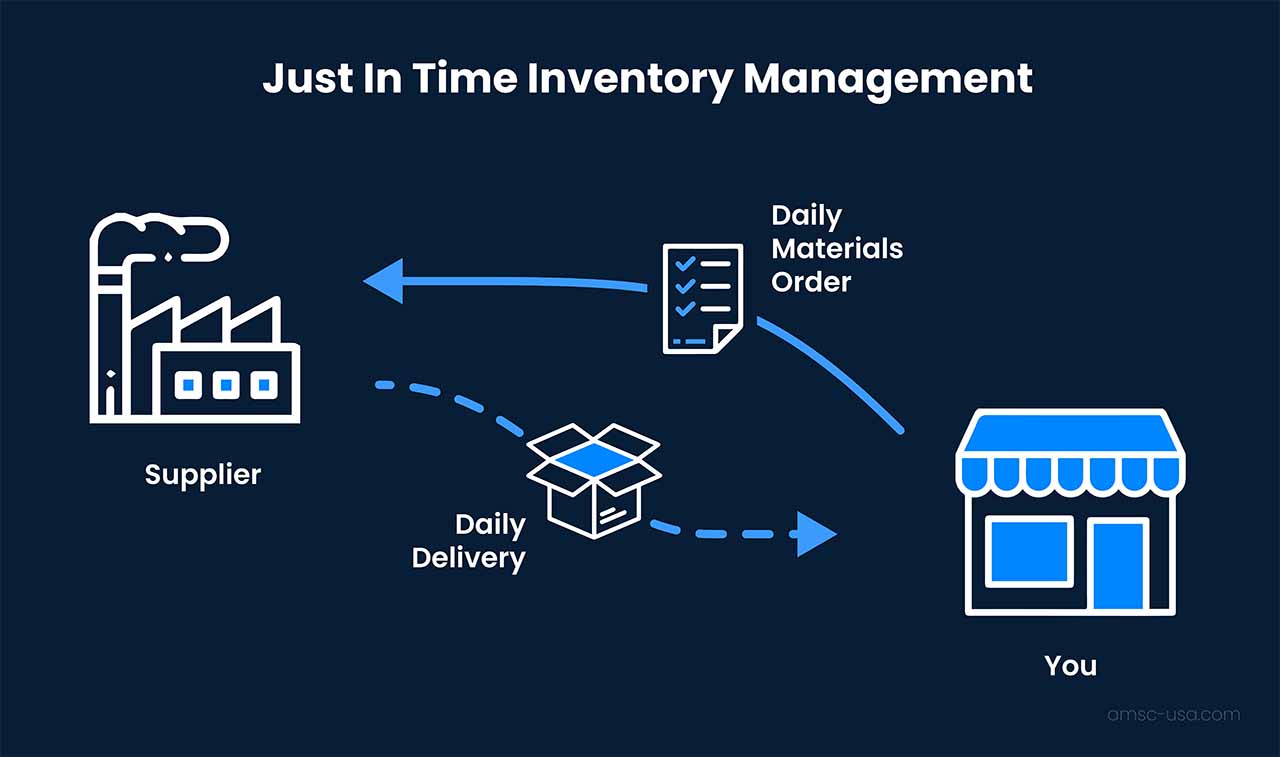

| Just-In-Time (JIT) Inventory Management | ||

|---|---|---|

| Implementing JIT inventory management helps minimize inventory holding costs. By closely monitoring demand and adjusting production accordingly, companies can reduce excess inventory. JIT also reduces the risk of stockouts, improving cash flow and lowering storage costs. | ||

| 5 | ||

| Energy Efficiency Measures | ||

|---|---|---|

| Implementing energy-efficient measures in production processes can lead to significant cost savings. Upgrading machinery and equipment to more energy-efficient alternatives can reduce electricity consumption. Installing energy monitoring systems and optimizing production schedules can help identify and eliminate energy waste. | ||

| 6 | ||

| Process Optimization and Continuous Improvement | ||

|---|---|---|

| Continuously optimizing production processes through lean methodologies can minimize costs. Identifying and eliminating non-value-added activities or process inefficiencies can result in cost reduction. Encouraging employee involvement and regularly reviewing and improving processes can lead to continuous cost minimization. | ||

| 7 | ||

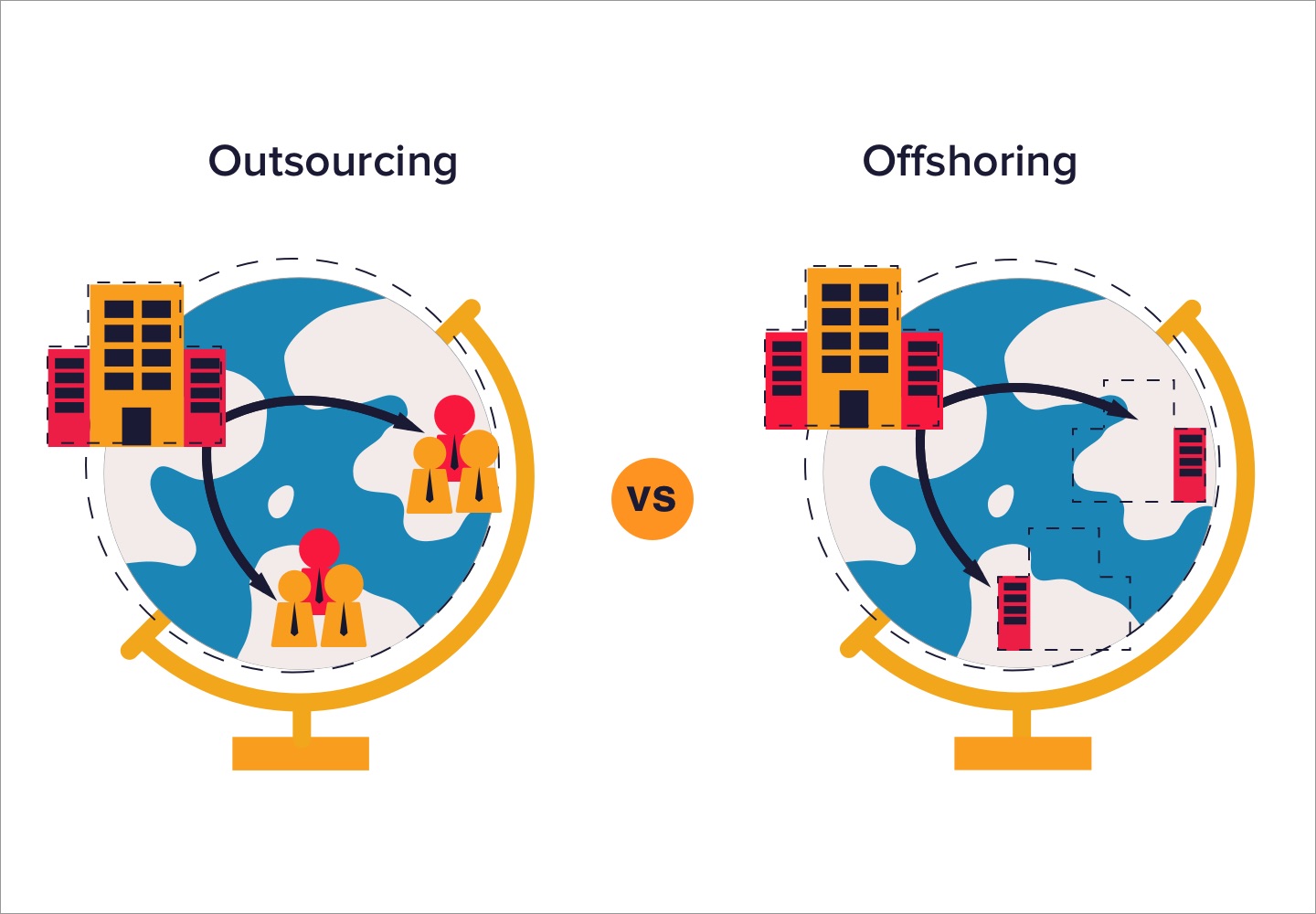

| Outsourcing and Offshoring | ||

|---|---|---|

| Outsourcing non-core activities or specific tasks to external vendors can lower production costs. Offshoring production to countries with lower labor costs can provide cost advantages. However, careful consideration should be given to quality control and potential risks associated with outsourcing/ offshoring. | ||

| 8 | ||

| Training and Development | ||

|---|---|---|

| Investing in employee training and development can result in cost minimization. Well-trained employees are more efficient, leading to increased productivity and reduced errors. Cross-training employees can also provide flexibility and minimize the need for additional labor. | ||

| 9 | ||

| Conclusion | ||

|---|---|---|

| Cost minimization strategies in production are crucial for businesses to maintain competitiveness. By implementing efficient resource allocation, embracing technology, and optimizing processes, companies can reduce production costs. It is important to regularly review and evaluate these strategies to ensure continuous improvement and sustained cost savings. | ||

| 10 | ||