COBB TEST IN PACKAGING Presentation

| Introduction to COBB Test in Packaging | ||

|---|---|---|

| The COBB test is a widely used method to measure the water absorbency of packaging materials. It is important to assess packaging materials' ability to resist water absorption to ensure product protection during transportation and storage. The COBB test provides valuable information about the suitability and quality of packaging materials. | ||

| 1 | ||

| Purpose of the COBB Test | ||

|---|---|---|

| The purpose of the COBB test is to determine the water absorbency of packaging materials. This test helps evaluate the effectiveness of packaging materials in protecting products from moisture. By measuring the water absorbency, packaging manufacturers can assess the potential risks associated with moisture exposure. | ||

| 2 | ||

| Procedure of the COBB Test | ||

|---|---|---|

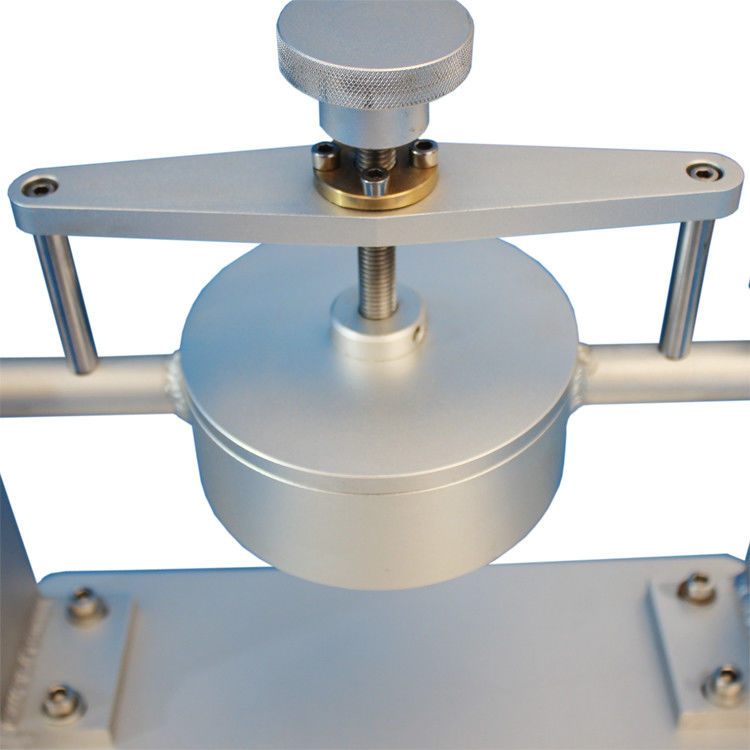

| The COBB test involves placing a standardized size sample of the packaging material on a horizontal surface. A specific volume of water is then poured onto the sample, and a specified time is allowed for absorption. After the given time, the excess water is removed, and the weight of the wet sample is measured. | ||

| 3 | ||

| Calculation of COBB Value | ||

|---|---|---|

| The COBB value is determined by subtracting the weight of the dry sample from the weight of the wet sample. The result is expressed in grams per square meter (g/ m²) or grams per square foot (g/ ft²). The higher the COBB value, the greater the water absorbency of the packaging material. | ||

| 4 | ||

| Factors Affecting COBB Test Results | ||

|---|---|---|

| The COBB test results can be influenced by various factors, including the porosity and composition of the packaging material. Environmental conditions, such as temperature and humidity, can also impact the test results. It is crucial to control these variables to obtain accurate and reliable COBB test measurements. | ||

| 5 | ||

| Importance of COBB Test in Packaging | ||

|---|---|---|

| The COBB test helps packaging manufacturers select materials with optimal water resistance for specific products. It aids in evaluating the performance of packaging materials in preventing moisture-related damages. By using the COBB test, companies can ensure the durability and functionality of their packaging solutions. | ||

| 6 | ||

| Advantages of COBB Test | ||

|---|---|---|

| The COBB test is a relatively simple and cost-effective method to assess water absorbency. It provides quantitative data that allows for easy comparison between different packaging materials. COBB test results can be used to improve packaging designs and optimize material selection. | ||

| 7 | ||

| Limitations of COBB Test | ||

|---|---|---|

| The COBB test only measures the surface water absorbency of packaging materials. It does not account for the potential effects of water penetration over time or through seams and edges. Additional tests or simulations may be necessary to evaluate packaging materials' long-term water resistance. | ||

| 8 | ||

| Applications of COBB Test | ||

|---|---|---|

| The COBB test is commonly used in the food and beverage industry to evaluate packaging materials for moisture-sensitive products. It is also relevant in industries such as pharmaceuticals, electronics, and cosmetics, where moisture protection is critical. The COBB test helps ensure product quality and safety by identifying potential risks associated with moisture exposure. | ||

| 9 | ||

| Conclusion | ||

|---|---|---|

| The COBB test is a valuable tool in packaging testing and quality control. By measuring water absorbency, it helps determine the suitability of packaging materials for protecting products from moisture. The COBB test plays a crucial role in ensuring the integrity and functionality of packaging solutions. | ||

| 10 | ||

| References (download PPTX file for details) | ||

|---|---|---|

| Smith, J. M. (2019). Packaging Materials: Sel... ASTM International. (2016). Standard test met... Hu, J., & Du, G. (2019). Moisture transport p... |  | |

| 11 | ||