A REAL TIME PROCESS MONITORING AND CONTROL IN INDUSTRIAL ROBOTS Presentation

| Introduction | ||

|---|---|---|

| Real-time process monitoring and control in industrial robots is crucial for optimizing productivity and ensuring operational efficiency. With advancements in technology, industrial robots have become more intelligent and capable of monitoring and controlling their own processes. Real-time process monitoring and control enables timely detection and correction of errors, improving quality and reducing downtime. | ||

| 1 | ||

| Importance of Real-Time Monitoring | ||

|---|---|---|

| Real-time monitoring allows for immediate identification of deviations from desired process parameters, enabling quick intervention and corrective actions. It ensures the consistency and accuracy of robot operations, minimizing errors and improving overall productivity. Real-time monitoring also provides valuable data for predictive maintenance, enhancing equipment reliability and reducing maintenance costs. |  | |

| 2 | ||

| Key Components of Real-Time Monitoring | ||

|---|---|---|

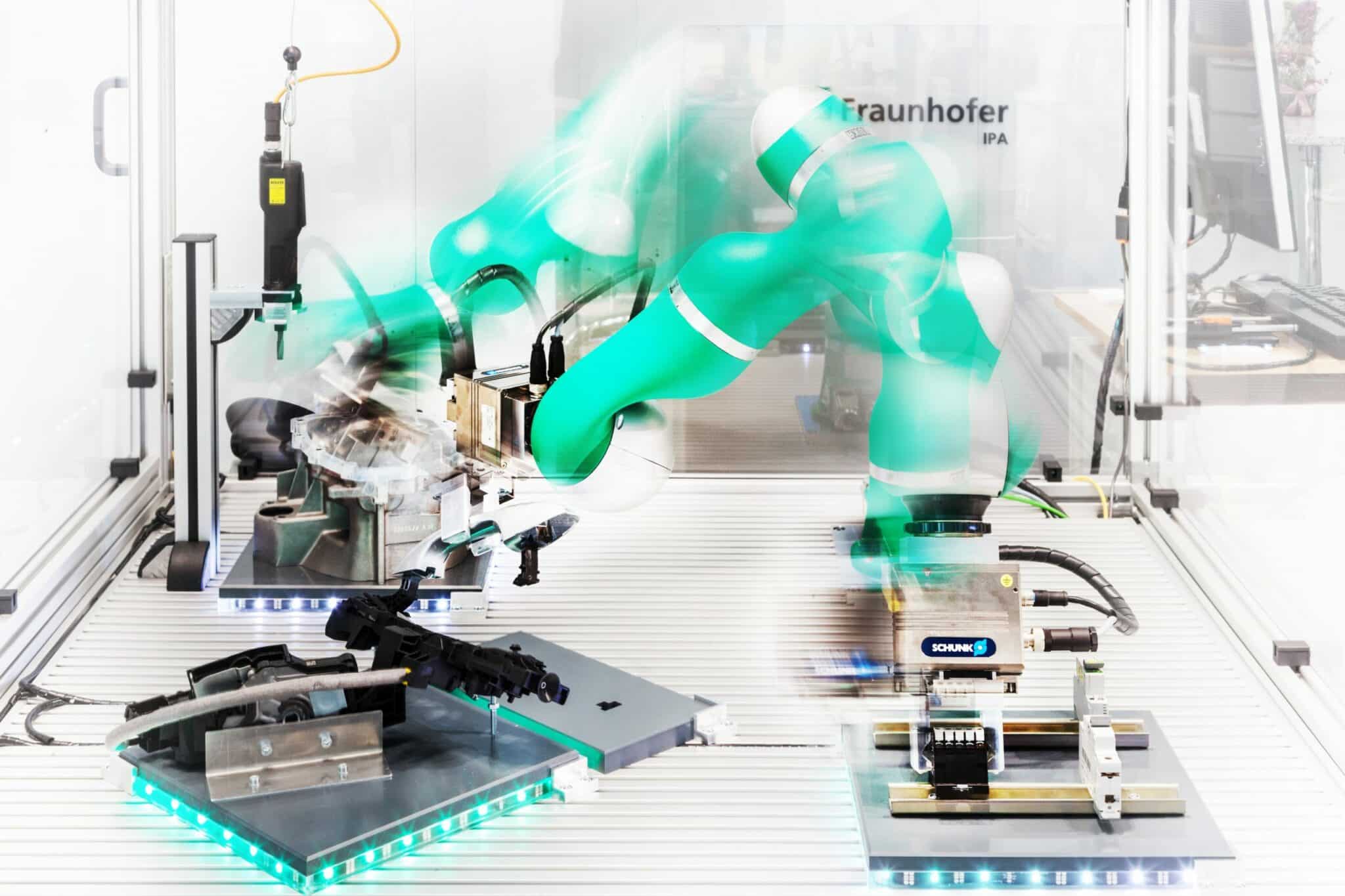

| Sensors: Industrial robots are equipped with various sensors such as force/ torque sensors, proximity sensors, and vision systems to monitor process variables. Data Acquisition: Real-time data acquisition systems collect data from sensors at high sampling rates to capture process dynamics accurately. Data Processing: Advanced algorithms and data analytics techniques are employed to analyze the collected data and extract meaningful insights. | ||

| 3 | ||

| Benefits of Real-Time Control | ||

|---|---|---|

| Real-time control allows for immediate adjustment of robot parameters, ensuring optimal performance and adaptability to changing process conditions. It enables real-time feedback control loops, allowing robots to continuously adjust their actions based on the monitored process variables. Real-time control enhances safety by enabling quick response to potential hazards or anomalies, minimizing risks to personnel and equipment. | ||

| 4 | ||

| Implementation Challenges | ||

|---|---|---|

| Real-time process monitoring and control require robust and reliable communication networks to transmit data between the robot and monitoring systems. The processing power and computational capabilities of the robot controller must be sufficient to handle the real-time monitoring and control tasks. Calibration and calibration drift issues in sensors need to be carefully addressed to ensure accurate and consistent data acquisition. | ||

| 5 | ||

| Applications in Quality Control | ||

|---|---|---|

| Real-time process monitoring and control enable early detection of defects or deviations from quality standards, minimizing waste and rework. It allows for automatic adjustments to maintain consistent product quality, reducing variations and ensuring customer satisfaction. Real-time monitoring also facilitates continuous improvement efforts by providing valuable data for root cause analysis and process optimization. | ||

| 6 | ||

| Applications in Predictive Maintenance | ||

|---|---|---|

| Real-time monitoring of critical robot components enables the detection of abnormal behavior or wear patterns, allowing for timely maintenance interventions. It helps in optimizing maintenance schedules and reducing unplanned downtime, increasing overall equipment effectiveness. Real-time monitoring also enables the prediction of remaining useful life for components, ensuring proactive replacement before failure occurs. | ||

| 7 | ||

| Case Study: Automotive Industry | ||

|---|---|---|

| Real-time process monitoring and control in industrial robots have revolutionized the automotive industry. Robots in assembly lines continuously monitor process variables such as torque, position, and force to ensure proper fitting and alignment of components. Real-time control allows for adaptive manufacturing, where robots can adjust their actions based on real-time feedback, improving efficiency and reducing defects. | ||

| 8 | ||

| Case Study: Food Packaging Industry | ||

|---|---|---|

| Real-time monitoring and control play a crucial role in maintaining food safety and quality in packaging processes. Robots equipped with vision systems detect contamination, improper sealing, or damaged packaging materials in real-time, preventing faulty products from reaching consumers. Real-time control ensures accurate filling, packaging, and labeling, minimizing wastage and enhancing productivity. | ||

| 9 | ||

| Conclusion | ||

|---|---|---|

| Real-time process monitoring and control in industrial robots offer numerous benefits, including improved productivity, quality, and safety. It enables proactive intervention, adaptive manufacturing, and predictive maintenance, leading to optimized operations. Continuous advancements in technology and the integration of artificial intelligence will further enhance the capabilities of real-time monitoring and control systems. | ||

| 10 | ||

| References (download PPTX file for details) | ||

|---|---|---|

| Smith, J. (2020). Real-time process monitorin... Johnson, M. (2018). Advancements in real-time... Lee, S., & Park, K. (2019). Real-time monitor... |  | |

| 11 | ||