3D Printer Presentation

| Introduction to 3D Printing | ||

|---|---|---|

| 3D printing is a revolutionary technology that allows for the creation of physical objects from digital designs. The process involves layering materials, such as plastics or metals, to build up the desired object. This technology has the potential to disrupt traditional manufacturing methods and enable customization on a whole new level. | ||

| 1 | ||

| How Does a 3D Printer Work? | ||

|---|---|---|

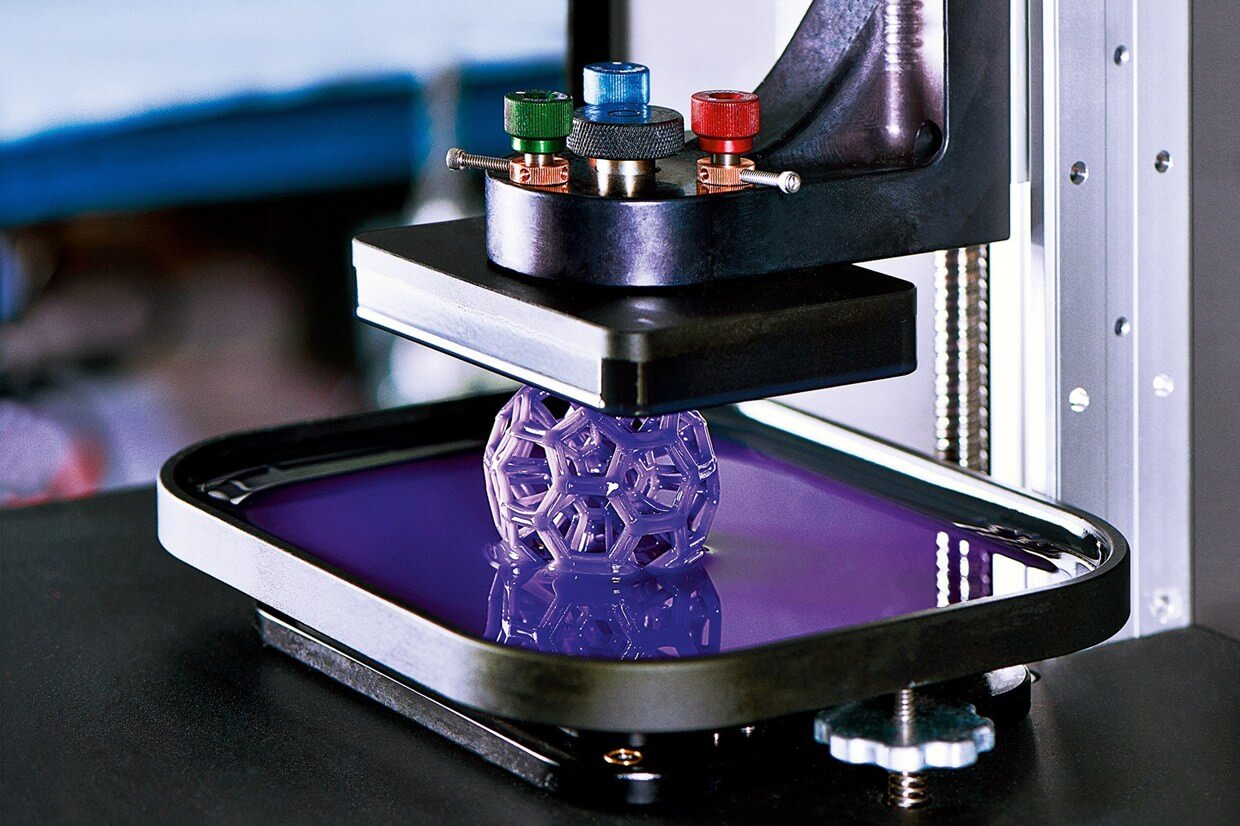

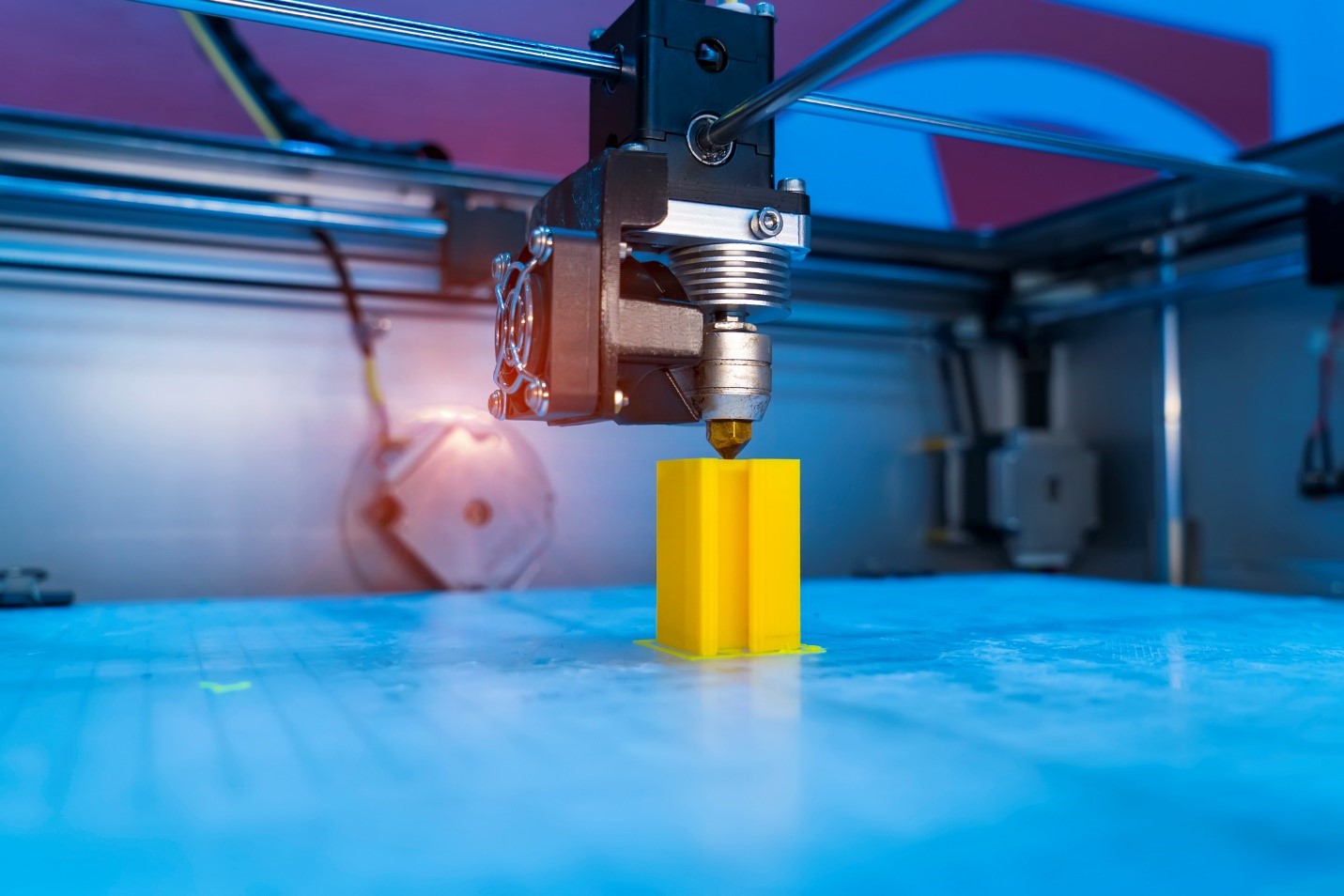

| A 3D printer works by following instructions from a digital file, typically a Computer-Aided Design (CAD) model. The printer uses a variety of techniques, such as fused deposition modeling (FDM) or stereolithography (SLA), to create objects layer by layer. The materials used, known as filaments or resins, are melted or cured to form the desired shape. | ||

| 2 | ||

| Types of 3D Printers | ||

|---|---|---|

| FDM printers, or filament-based printers, are the most common and affordable type of 3D printer. SLA printers use photopolymer resins that are cured using ultraviolet light. SLS printers, or selective laser sintering printers, use lasers to solidify powdered materials. | ||

| 3 | ||

| Applications of 3D Printing | ||

|---|---|---|

| 3D printing has found applications in various industries, including healthcare, automotive, aerospace, and architecture. In healthcare, it is used for creating custom prosthetics, implants, and even organs. Industries like automotive and aerospace use 3D printing for rapid prototyping and manufacturing complex parts. | ||

| 4 | ||

| Benefits of 3D Printing | ||

|---|---|---|

| Customization: 3D printing allows for the creation of personalized products tailored to individual needs. Rapid Prototyping: It enables quick iteration and testing of designs, reducing time and cost in product development. Reduced Waste: Traditional manufacturing methods often result in significant material wastage, whereas 3D printing uses only the materials necessary for the object. | ||

| 5 | ||

| Limitations of 3D Printing | ||

|---|---|---|

| Size Constraints: Most consumer-grade 3D printers have limited build volumes, restricting the size of objects that can be printed. Material Limitations: The range of materials available for 3D printing is expanding, but certain properties like strength and flexibility can still be limited. Speed: 3D printing can be a slow process, especially for complex or large objects, which may require hours or even days to complete. | ||

| 6 | ||

| Future Trends in 3D Printing | ||

|---|---|---|

| Advancements in materials: Researchers are constantly developing new materials with enhanced properties for 3D printing. Multi-material and multi-color printing: The ability to print objects with multiple materials or colors simultaneously is an area of active research. Bioprinting: The field of bioprinting aims to print living tissues and organs, potentially revolutionizing healthcare. | ||

| 7 | ||

| Challenges in 3D Printing | ||

|---|---|---|

| Intellectual Property: 3D printing raises concerns related to copyright infringement, as designs can easily be replicated. Quality Control: Ensuring consistent quality and reliability in 3D printed objects is a challenge that needs to be addressed. Sustainability: As 3D printing becomes more widespread, managing the environmental impact of discarded prints and wasted materials is crucial. | ||

| 8 | ||

| Conclusion | ||

|---|---|---|

| 3D printing is a transformative technology with vast potential to reshape industries and enable innovation. As the technology advances, it will become more accessible, affordable, and versatile. Embracing 3D printing opens up new possibilities for customization, rapid prototyping, and sustainable manufacturing. | ||

| 9 | ||

| Questions and Answers | ||

|---|---|---|

| Use this slide to engage the audience and address any questions they may have about 3D printing. Your second bullet Your third bullet | ||

| 10 | ||