3 Phase Alternator Presentation

| Introduction to 3 Phase Alternator | ||

|---|---|---|

| A 3 phase alternator is an electrical device that converts mechanical energy into electrical energy. It is commonly used in power generation systems and industrial applications. Unlike single phase alternators, 3 phase alternators generate three separate AC voltages that are 120 degrees out of phase with each other. | ||

| 1 | ||

| Working Principle of 3 Phase Alternator | ||

|---|---|---|

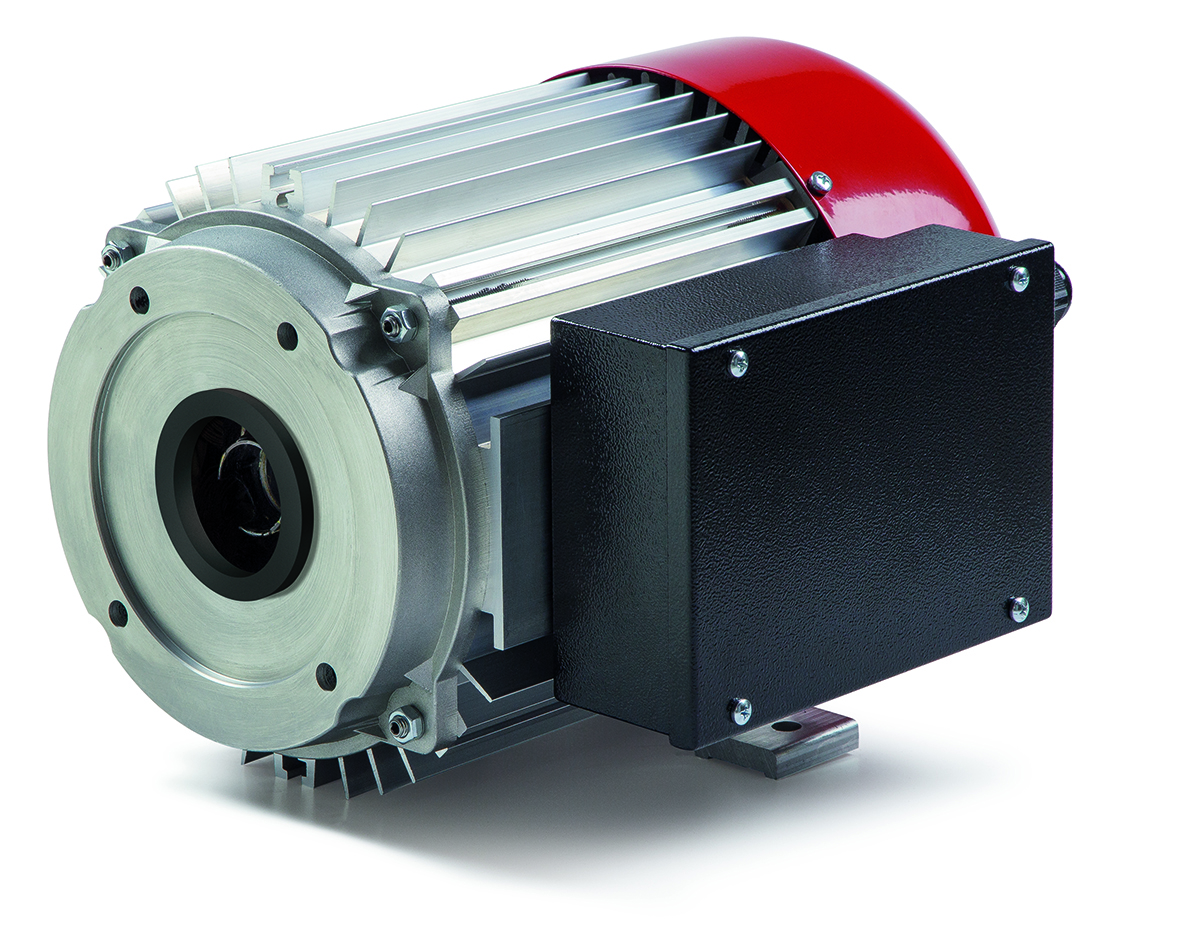

| The 3 phase alternator consists of a rotor and a stator. The rotor is the rotating part of the alternator that generates a magnetic field. The stator is the stationary part that contains three sets of windings, each connected to one phase. | ||

| 2 | ||

| Advantages of 3 Phase Alternator | ||

|---|---|---|

| Higher power output: 3 phase alternators can deliver more power compared to single phase alternators. Balanced power supply: The three phases provide a more balanced load distribution, reducing voltage fluctuations. Efficient power transmission: 3 phase power allows for efficient transmission over long distances with less energy loss. | ||

| 3 | ||

| Applications of 3 Phase Alternator | ||

|---|---|---|

| Power generation: 3 phase alternators are used in power plants to generate electricity for residential, commercial, and industrial use. Electric motors: Three-phase motors are commonly used in various applications such as pumps, compressors, and machine tools. Industrial processes: Many industrial processes such as welding, heating, and large-scale manufacturing rely on 3 phase power. | ||

| 4 | ||

| Types of 3 Phase Alternator | ||

|---|---|---|

| Synchronous alternator: It operates at a constant speed and is synchronized with the frequency of the electrical grid. Induction alternator: It operates at variable speeds and is mainly used in small-scale applications like wind turbines. Your third bullet | ||

| 5 | ||

| Maintenance and Troubleshooting of 3 Phase Alternator | ||

|---|---|---|

| Regular inspection: Periodic inspection of the alternator's components, connections, and cooling systems is essential to ensure proper functioning. Lubrication: Proper lubrication of bearings and other moving parts helps to reduce friction and extend the lifespan of the alternator. Troubleshooting: In case of issues, troubleshooting involves checking the connections, voltage outputs, and rectifying any faults. | ||

| 6 | ||

| Safety Considerations for 3 Phase Alternator | ||

|---|---|---|

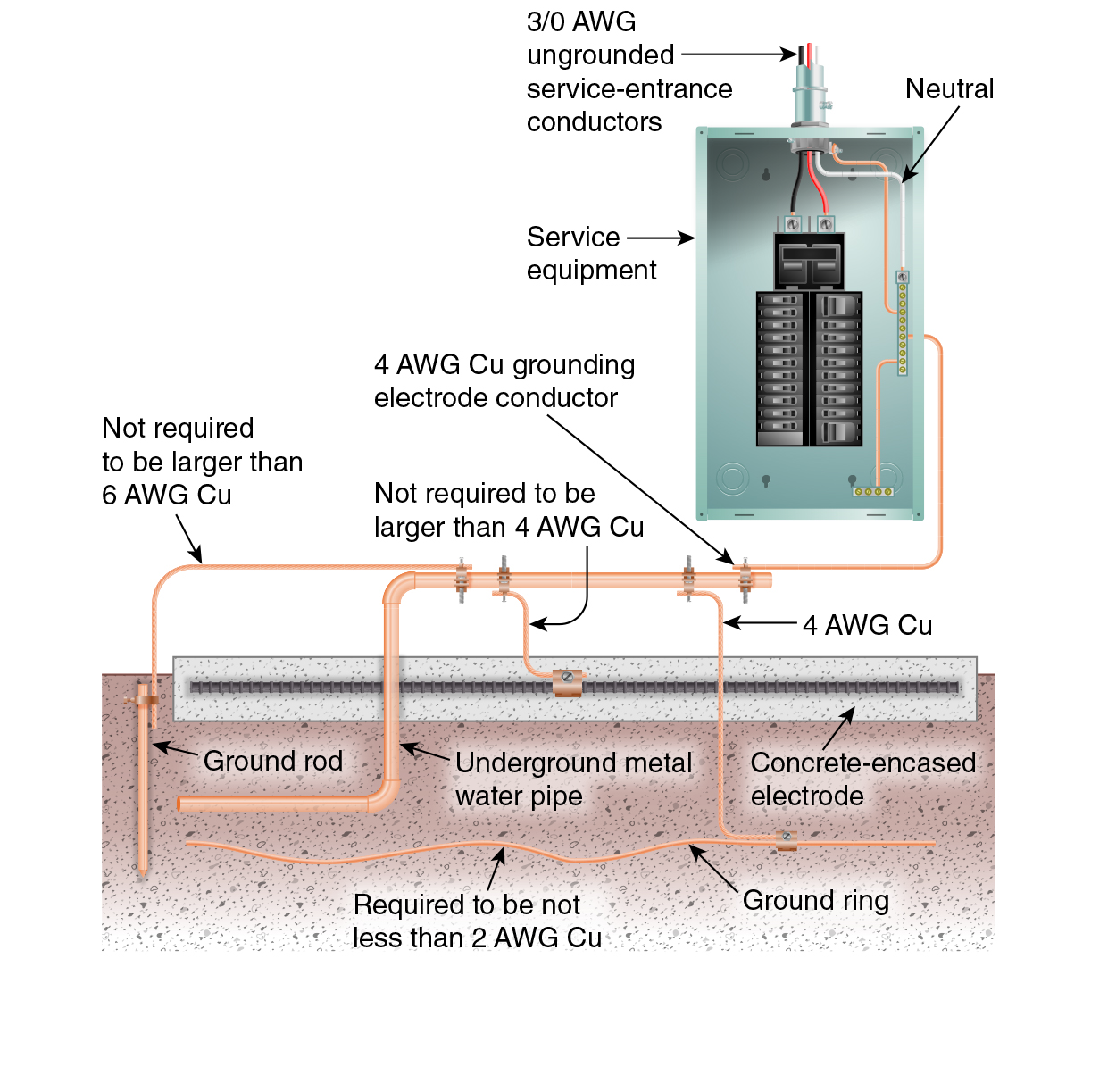

| Proper grounding: Ensuring proper grounding of the alternator and electrical system reduces the risk of electrical shocks and equipment damage. Overload protection: Installing appropriate overload protection devices prevents excessive current flow and protects the alternator from damage. Regular maintenance: Regular maintenance helps identify potential hazards and ensures the safe operation of the alternator. | ||

| 7 | ||

| Summary | ||

|---|---|---|

| 3 phase alternators are widely used in power generation and industrial applications. They provide higher power output, balanced power supply, and efficient transmission. Regular maintenance and adherence to safety precautions are crucial for reliable and safe operation. | ||

| 8 | ||

| References (download PPTX file for details) | ||

|---|---|---|

| "Electric Power Systems: A Conceptual Introdu... "Electrical Machines, Drives, and Power Syste... "Electrical Power Systems" by C.L. Wadhwa... |  | |

| 9 | ||