Bakelite Prepation,properties, Applications Presentation

| Introduction to Bakelite | ||

|---|---|---|

| Bakelite is a synthetic thermosetting polymer. It was the first commercially successful plastic. Developed by Leo Hendrik Baekeland in 1907. | ||

| 1 | ||

| Preparation of Bakelite | ||

|---|---|---|

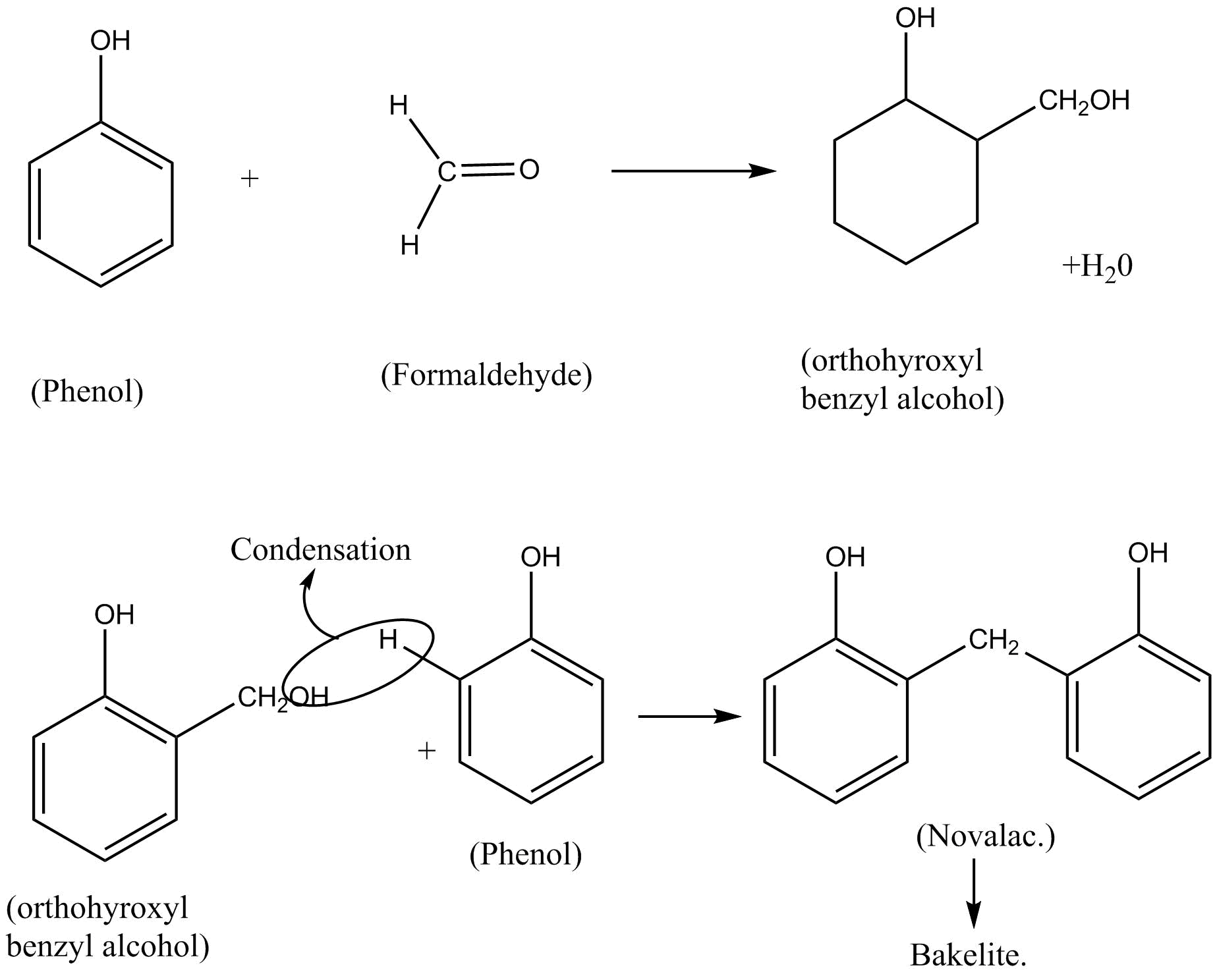

| Bakelite is prepared by the condensation reaction of phenol and formaldehyde. The reaction is catalyzed by an acidic or basic catalyst. The resulting resin can be molded into desired shapes. | ||

| 2 | ||

| Properties of Bakelite | ||

|---|---|---|

| Excellent electrical insulator. High heat resistance. Chemical resistant. | ||

| 3 | ||

| Applications of Bakelite | ||

|---|---|---|

| Electrical insulators - used in electrical switches, connectors, and circuit boards. Automotive industry - used for distributor caps, brake pads, and electrical components. Consumer goods - handles for kitchen utensils, jewelry, and decorative items. | ||

| 4 | ||

| Advantages of Bakelite | ||

|---|---|---|

| High resistance to heat and chemicals. Excellent electrical insulation properties. Can be molded into complex shapes and sizes. | ||

| 5 | ||

| Limitations of Bakelite | ||

|---|---|---|

| Brittle and prone to cracking under impact. Limited color options - usually dark brown or black. Cannot be recycled easily. | ||

| 6 | ||

| Future Trends in Bakelite | ||

|---|---|---|

| Research is being conducted to improve impact resistance. Development of alternative colors and finishes. Exploring more sustainable manufacturing processes. | ||

| 7 | ||

| Conclusion | ||

|---|---|---|

| Bakelite is a versatile and widely used synthetic polymer. Its excellent properties make it suitable for various applications. Ongoing advancements aim to enhance its performance and sustainability. | ||

| 8 | ||